349

The Cat ® 349 excavator brings premium performance with simple-to-use technologies like Cat GRADE with 2D, Grade Assist, and Payload – all standard equipment from the factory to boost your operator efficiencies up to 45 percent. Combine these with standard safety features like E-fence and all-new ROPS cab, longer maintenance intervals that lower your maintenance costs up to 15 percent, and a power system that improves fuel efficiency up to 25 percent and you have a low-cost-per-unit-of-production excavator that’s perfect for your applications.

Not all features available in all regions. Consult your Cat dealer for specific configurations available in your region.

Not all features available in all regions. Consult your Cat dealer for specific configurations available in your region.

Net Power - ISO 9249

405 HP

Engine Model

C13

Engine Power - ISO 14396

406 HP

Specification

Value

Net Power - ISO 9249

405 HP

Engine Model

C13

Engine Power - ISO 14396

406 HP

Bore

5 in

Stroke

6 in

Displacement

763 in³

Specification

Value

Main System - Maximum Flow

779 l/min (206 gal/min)

Maximum Pressure - Equipment

5076 psi

Maximum Pressure - Equipment - Lift Mode

5511 psi

Maximum Pressure - Travel

5076 psi

Maximum Pressure - Swing

3771 psi

Specification

Value

Swing Speed

8.44 r/min

Maximum Swing Torque

138,000 ft·lbf

Specification

Value

Operating Weight

104,700 lb

Specification

Value

Fuel Tank Capacity

188.9 gal (US)

Cooling System

13.7 gal (US)

Engine Oil

10.6 gal (US)

Swing Drive - Each

2.8 gal (US)

Final Drive - Each

4 gal (US)

Hydraulic System - Including Tank

145.3 gal (US)

Hydraulic Tank

57.3 gal (US)

Specification

Value

Boom

Reach 6.9m (22'8")

Stick

R3.35m (11'0")

Bucket

SD 2.41 m³ (3.15 yd³)

Shipping Height - Top of Cab

10.6 ft

Handrail Height

11.1 ft

Shipping Length

39.1 ft

Tail Swing Radius

12.3 ft

Counterweight Clearance

4.2 ft

Ground Clearance

1.6 ft

Track Length

17.6 ft

Track Length to Center of Rollers

14.3 ft

Track Gauge

9 ft

Transport Width

3340 mm

Specification

Value

Maximum Digging Depth

25.3 ft

Boom

Reach 6.9m (22'8")

Stick

R3.35m (11'0")

Bucket

SD 2.41 m³ (3.15 yd³)

Maximum Reach at Ground Level

38.6 ft

Maximum Cutting Height

35.2 ft

Maximum Loading Height

24.2 ft

Minimum Loading Height

8.9 ft

Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

22.8 ft

Maximum Vertical Wall Digging Depth

17.8 ft

Bucket Digging Force - ISO

60,850 lbf

Stick Digging Force - ISO

47,680 lbf

- Increase operating efficiency up to 45 percent with standard Cat technologies that lower operator fatigue and operating costs, including fuel consumption and daily maintenance.

- Get up to 25 percent higher fuel efficiency – more work per unit of fuel – than the Cat 349D2 excavator.

- The C13 engine meets Brazil MAR-1 and China Nonroad Stage IIIe mission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- Match the excavator to the job with three power modes – Power, Smart, and Eco. Smart mode automatically matches engine and hydraulic power to digging conditions, providing max power when needed and reducing power when it isn’t to help save fuel.

- The new high-efficiency hydraulic fan cools the engine on demand to help reduce fuel consumption; available reverse function makes it easy to keep cores clean.

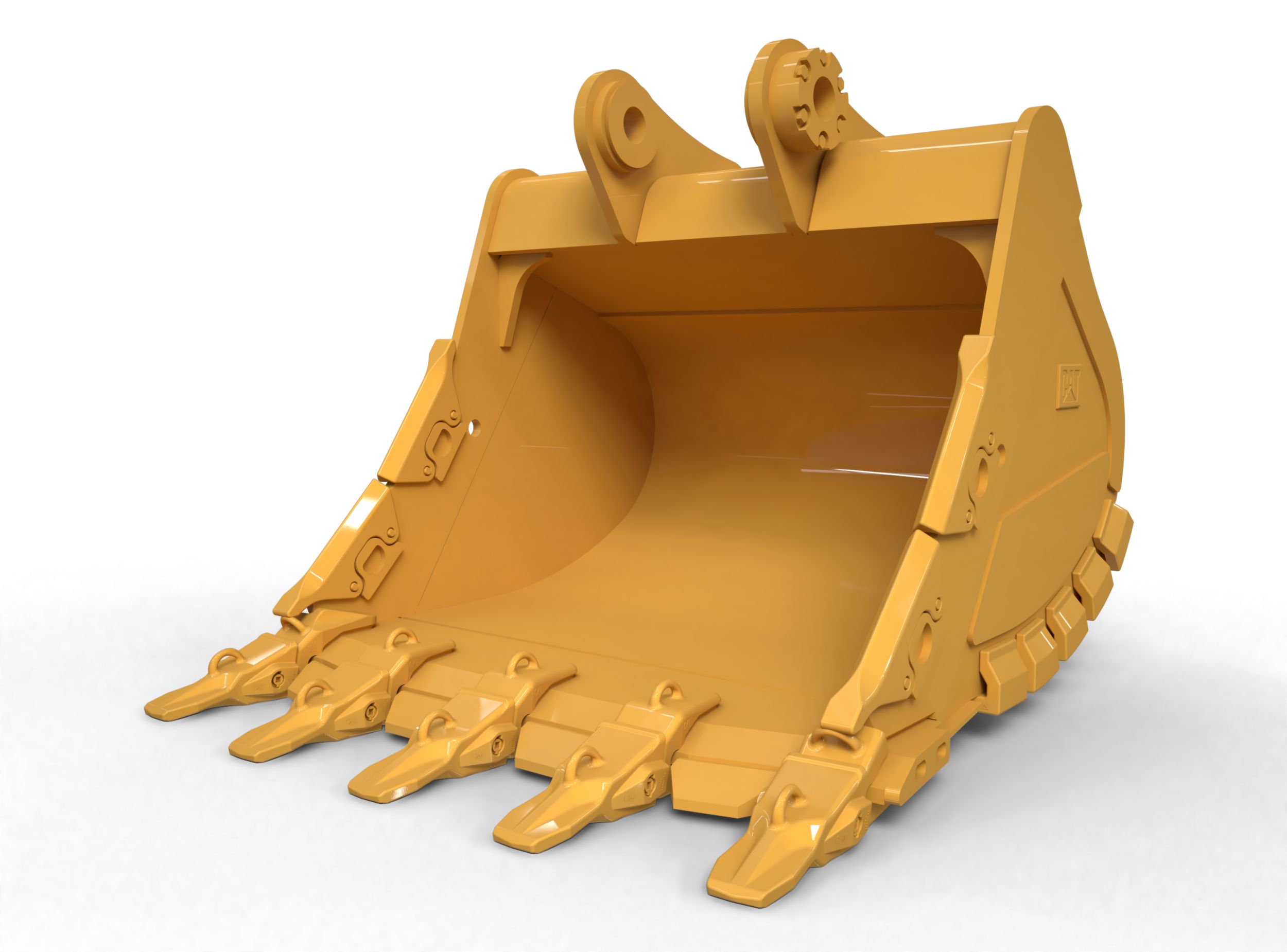

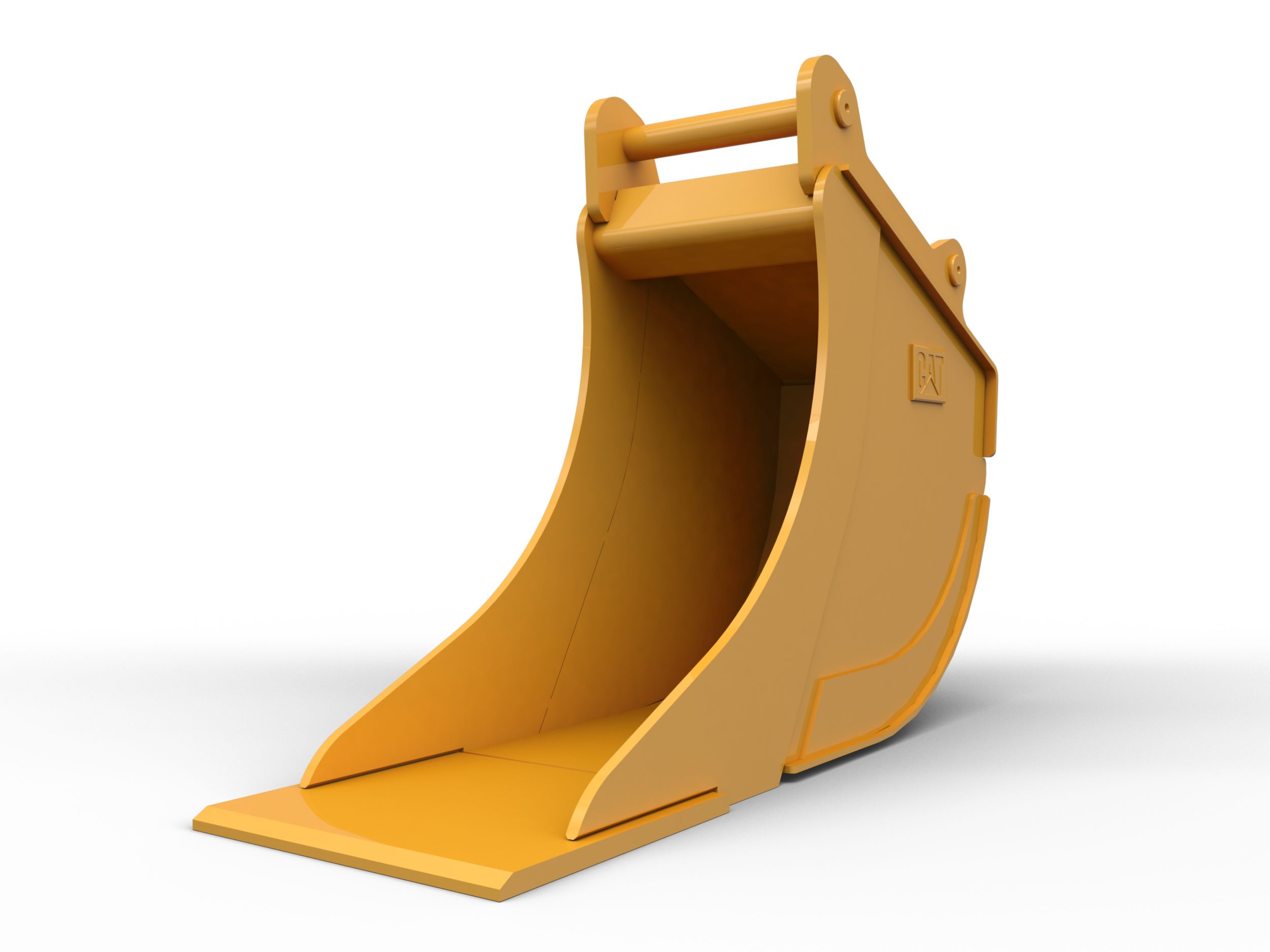

- New self-sharpening Advansys™ bucket tips increase production and lower costs.

- Auxiliary hydraulic options give you the versatility to use a wide range of Cat attachments.

- Don’t let the temperature stop you from working. This excavator has a high-ambient capability of 52° C (125° F) and cold start capability of –18° C (0° F).

- Boost productivity up to 45 percent versus traditional grading with standard Cat GRADE with 2D system – includes indicate-only and laser capability.

- Standard Grade Assist: Stay on grade – simply and effortlessly – with single-lever digging.

- Set your desired bucket angle and let Bucket Assist automatically maintain the angle in sloping, leveling, fine grading, and trenching applications

- Keep the tracks on ground in lifting and hard digging with Boom Assist.

- Automatically stop excavator swing at operator-defined set points in truck loading and trenching applications with Swing Assist, which will help you use less effort and consume less fuel.

- Standard Cat PAYLOAD on-board weighing system: Achieve precise load targets and increase loading efficiency with on-the-go weighing and real-time estimates of your payload without swinging.

- Combine Payload with VisionLink® and remotely manage your production targets.

- Take payload data with you. The monitor’s USBport lets you download your results from one shift all the way up to 30 days of work so can manage your progress without needing an internet connection or VisionLink® subscription.

- Upgrade to optional Cat GRADE with Advanced 2D: Create and edit grade designs with ease on a second high-resolution 254 mm (10 in) touchscreen monitor.

- Upgrade to optional Cat GRADE with 3D: Create and edit designs with ease and see the front linkage’s full range of motion on a second high-resolution 254 mm (10 in) touchscreen monitor.

- Know the excavator’s exact position relative to GPS and GLONASS systems. The machine automatically compensates for excavator pitch and roll caused by sloping ground conditions.

- Remote Troubleshoot connects you to a dealer service pro to help solve your problem and quickly get you to work.

- Remote Flash works around your schedule to ensure your machine’s software is up to date for optimal performance.

- The Cat App helps you manage fleet location, hours, and maintenance schedules; it also alerts you for required maintenance and even allows you to request service from your local Cat dealer.

- Standard Product Link™ provides location, machine hours, fuel usage, productivity, idle time, diagnostic codes, and other machine data on demand through VisionLink online interface, helping you improve job site efficiency with lower operating costs.

- Already invested in another brand’s 3D system? No problem. Standard Cat technology like GRADE with 2D can readily integrate with that system to give you the precise results you need.

- Choose between Comfort and Deluxe cabs – both with automatic climate control.

- Sit in wide seats that adjust for all size operators; stay warm with the Deluxe heated seat.

- Enjoy wide spacing between consoles for a more comfortable environment.

- Get in and out of the cab easier using the tip-up left console (Deluxe cab only).

- Advanced viscous mounts reduce cab vibration up to 50 percent over previous excavator models.

- Control the excavator comfortably with easy-to-reach controls all located in front of you.

- Stow your gear with plenty of in-cab storage beneath and behind the seat, overhead, and in the consoles. A cup holder, document holder, bottle holder, and coat hook are also provided.

- Use the standard radio’s USB ports and Bluetooth® technology to connect personal devices and make hands-free calls.

- Start the engine with a push button; use a Bluetooth key fob, smartphone app, or the unique Operator ID function.

- Program each joystick button, including power mode, response, and pattern, using Operator ID; the machine will remember what you set each time you go to work.

- Automatic hydraulic oil warm up gets you to work faster in cold temperatures and helps prolong the life of components.

- Navigate quickly on the standard high-resolution 203 mm (8 in) touchscreen monitor, or with the optional 254 mm (10 in)touchscreen monitor, or with the aid of the jog dial control.

- A second 254 mm (10 in) monitor is available for the advanced grade control and Cat GRADE with 3D.

- Not sure how a function works or how to maintain the excavator? Always have the operator’s manual at your fingertips in the touchscreen monitor.

- The Cat PL161 Attachment Locator is a Bluetooth device that makes finding your attachments and other gear quick and easy. The excavator's onboard Bluetooth reader or Cat App on your phone will locate the device automatically.

- Save more time and energy with the available work tool recognition feature. A simple shake of the attached tool confirms its identity; it also ensures all the attachment settings are correct so you can get to work quickly and efficiently.

- Auto hammer stop helps you prevent unnecessary wear and tear on the attachment and excavator. Simply enable it through the monitor, and you and your fellow operators will be warned after 15 seconds of continuous firing followed by automatic shutoff at 30 seconds.

- Expect up to 15 percent less maintenance cost than the 349D2 due to extended service intervals. (Savings calculated over 12,000 machine hours.)

- Check hydraulic system oil and easily drain fuel system water and fuel tank water from ground level.

- Track your excavator’s filter life and maintenance intervals via the in-cab monitor.

- Change all fuel filters at a synchronized 1,000 hours. Oil and fuel filters grouped and located on right-hand side of machine for easy maintenance.

- The new air intake filter with pre-cleaner has double the dust holding capacity of the previous air intake filter.

- The new hydraulic oil filter provides improved filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and longer life with a 3,000 hour replacement interval – 50 percent longer than previous filter designs.

- The new high-efficiency hydraulic fan has an optional automatic reverse function to keep cores free from debris, eliminating the need for any operator interaction.

- S∙O∙S ports simplify maintenance and allow for quick, easy extraction of fluid samples for analysis.

- Standard 2D E-Fence integrated right out of the factory prevents the excavator from moving outside of operator-defined set points.

- Lift Assist helps you avoid tipping by letting you know if your load is within the excavator’s safe working range limits.

- The standard ROPS cab meets ISO 12117-2:2008 requirements.

- A travel direction indicator helps operators know which way to activate the travel levers.

- Enjoy great visibility into the trench, in each swing direction, and behind you with the help of smaller cab pillars, larger windows, and a flat engine hood design.

- A ground-level shutoff switch stops all fuel to the engine when activated and shuts down the machine.

- A rearview camera is standard. Upgrade to 360° visibility and you’ll easily visualize objects and personnel around the excavator in a single view.

- Serrated steps and anti-skid punch plate on the service platform help prevent slipping.

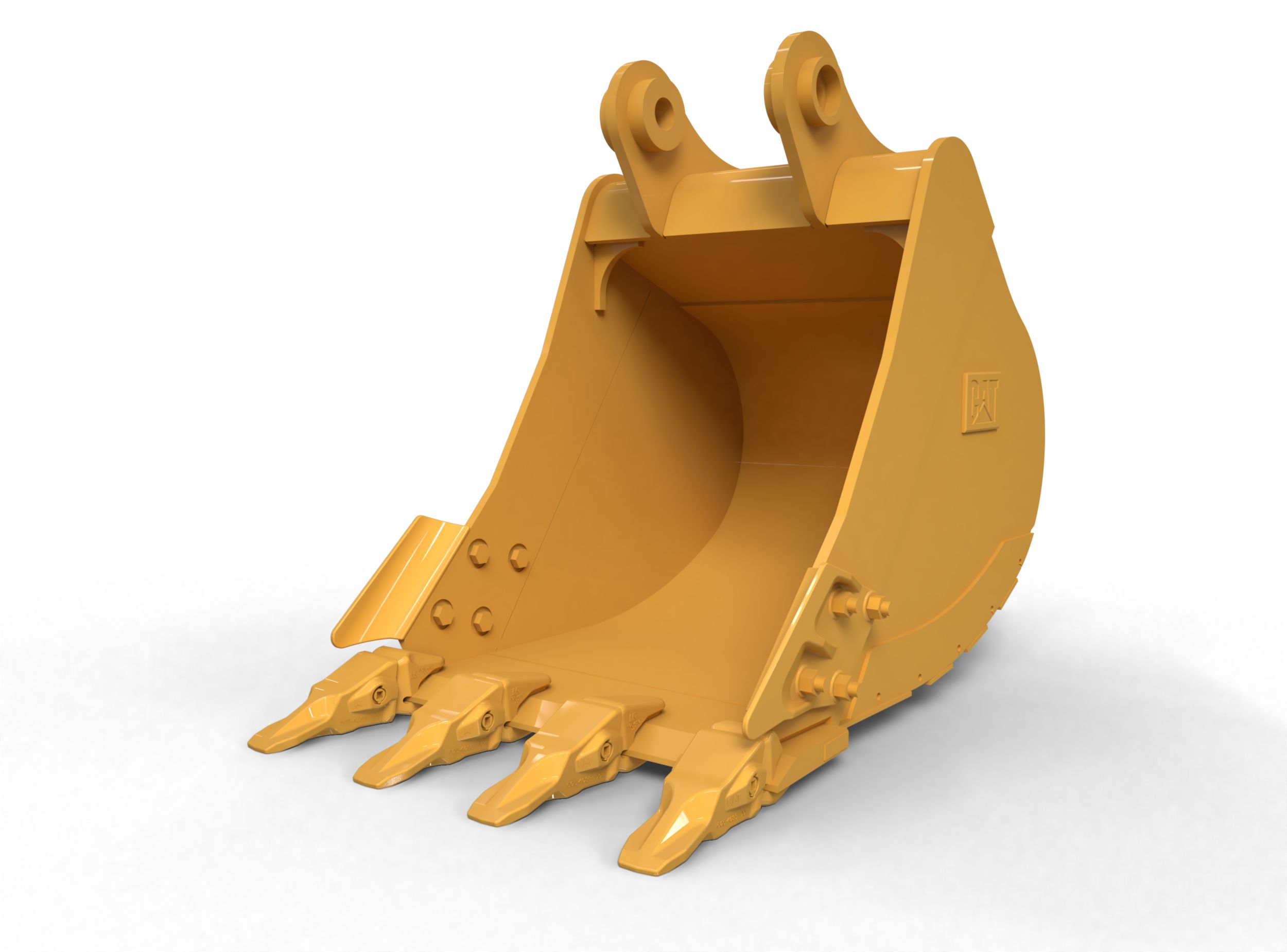

General Duty Bucket 1650 mm (65 in): 540-4108

General Duty Bucket 1500 mm (59 in): 561-0625

General Duty Bucket 1650 mm (65 in): 541-1739

General Duty Bucket 600 mm (24 in): 550-9443

General Duty - Leveling Edge Bucket 1000 mm (39 in): 462-8168

General Duty Bucket 1650 mm (65 in): 540-4111

General Duty - Leveling Edge Bucket 800 mm (31 in): 485-7622

General Duty - Leveling Edge Bucket 650 mm (25 in): 485-7621

General Duty - Leveling Edge Bucket 1000 mm (39 in): 477-3378

General Duty - Leveling Edge Bucket 1300 mm (51 in): 477-3380

General Duty - Leveling Edge Bucket 1200 mm (47 in): 477-3379

General Duty - Leveling Edge Bucket 1400 mm (55 in): 477-3381

General Duty - Leveling Edge Bucket 1500 mm (59 in): 477-3382

General Duty Bucket 750 mm (30 in): 550-9444

General Duty Bucket 1300 mm (51 in): 550-9447

General Duty Bucket 1200 mm (48 in): 550-9446

General Duty Bucket 1400 mm (55 in): 550-9448

General Duty Bucket 1200 mm (48 in): 550-9635

General Duty Bucket 900 mm (35 in): 550-9633

General Duty Bucket 1050 mm (42 in): 550-9634

General Duty Bucket 750 mm (30 in): 550-9668

General Duty Bucket 900 mm (36 in): 550-9669

General Duty Bucket 750 mm (30 in): 550-9469

General Duty Bucket 1050 mm (42 in): 550-9445

General Duty Bucket 1000 mm (39 in): 550-9470

General Duty Bucket 1200 mm (48 in): 550-9471

General Duty - Leveling Edge Bucket 1200 mm (48 in): 455-0750

General Duty Bucket 1500 mm (59 in): 541-1738

General Duty Bucket 1800 mm (71 in): 540-4110

General Duty Bucket 1650 mm (65 in): 541-1741

General Duty - Leveling Edge Bucket 1200 mm (47 in): 455-0749

General Duty Bucket 1200 mm (47 in): 550-9765

General Duty Bucket 750 mm (30 in): 550-9763

General Duty Bucket 1050 mm (41 in): 550-9764

General Duty Bucket 1350 mm (54 in): 550-9766

General Duty Bucket 600 mm (24 in): 550-9464

General Duty Bucket 600 mm (24 in): 550-9664

General Duty - Leveling Edge Bucket 650 mm (25 in): 485-7488

General Duty - Leveling Edge Bucket 800 mm (31 in): 485-7596

General Duty Bucket 1050 mm (42 in): 550-9438

General Duty Bucket 1200 mm (48 in): 550-9439

General Duty Bucket 1200 mm (48 in): 550-9631

General Duty Bucket 1200 mm (48 in): 462-9435

General Duty Bucket 1300 mm (51 in): 550-9665

General Duty Bucket 1300 mm (51 in): 550-9632

General Duty Bucket 1300 mm (51 in): 550-9440

General Duty Bucket 1300 mm (51 in): 550-9441

General Duty Bucket 1300 mm (51 in): 462-9436

General Duty Bucket 1400 mm (55 in): 550-9666

General Duty Bucket 1400 mm (55 in): 550-9466

General Duty - Leveling Edge Bucket 1400 mm (55 in): 468-3206

General Duty Bucket 1400 mm (55 in): 462-9437

General Duty Bucket 1500 mm (60 in): 550-9467

General Duty - Leveling Edge Bucket 1500 mm (60 in): 468-1691

General Duty - Leveling Edge Bucket 1500 mm (59 in): 462-9438

General Duty Bucket 1500 mm (60 in): 550-9762

General Duty - Leveling Edge Bucket 1600 mm (63 in): 462-9439

General Duty Bucket 2000 mm (79 in): 518-9353

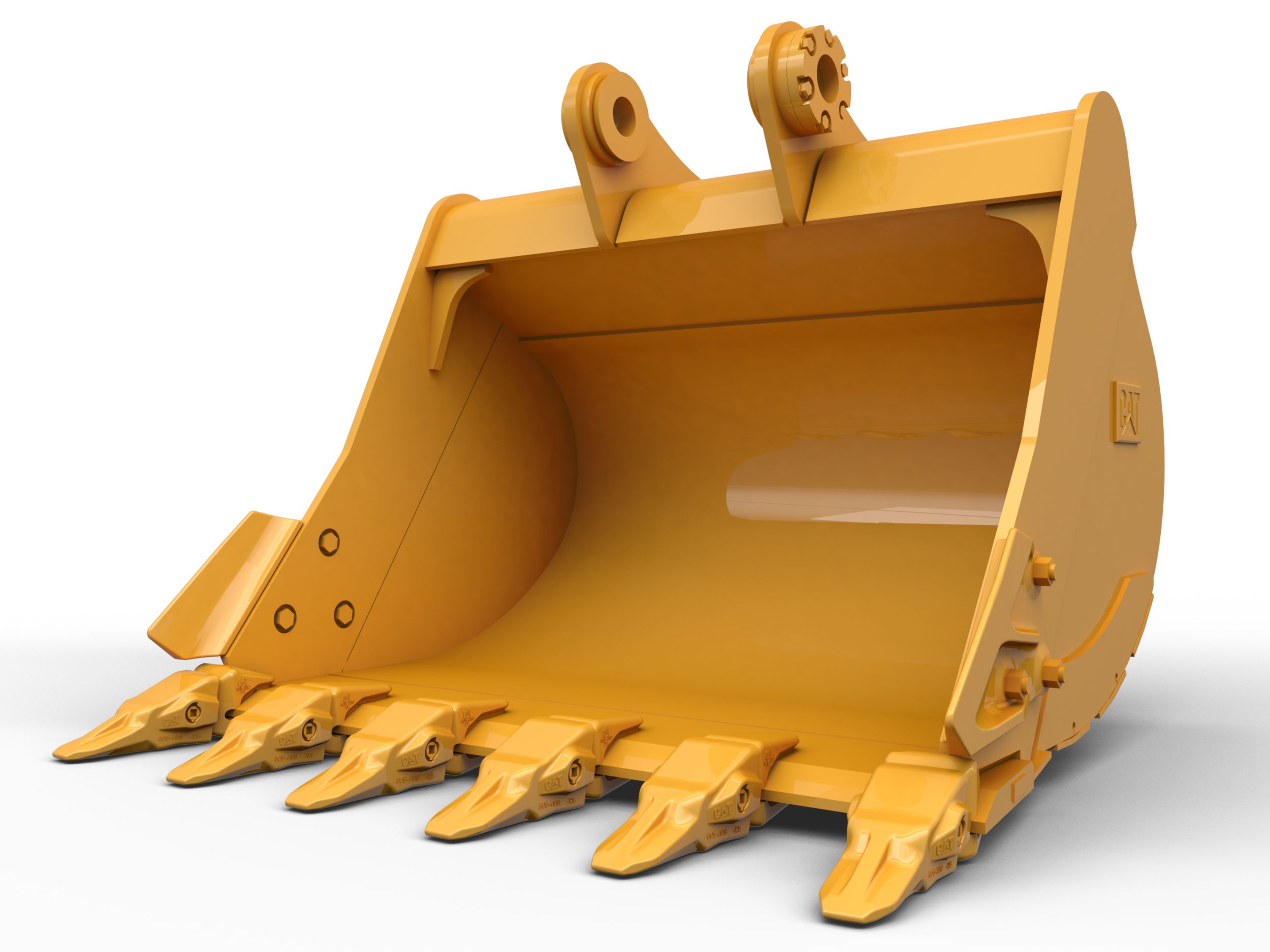

Extreme Duty Bucket 1650 mm (65 in): 518-9341

Extreme Duty Bucket 1550 mm (61 in): 518-9340

Extreme Duty Bucket 1700 mm (67 in): 518-9331

Extreme Duty Bucket 1950 mm (77 in): 528-8154

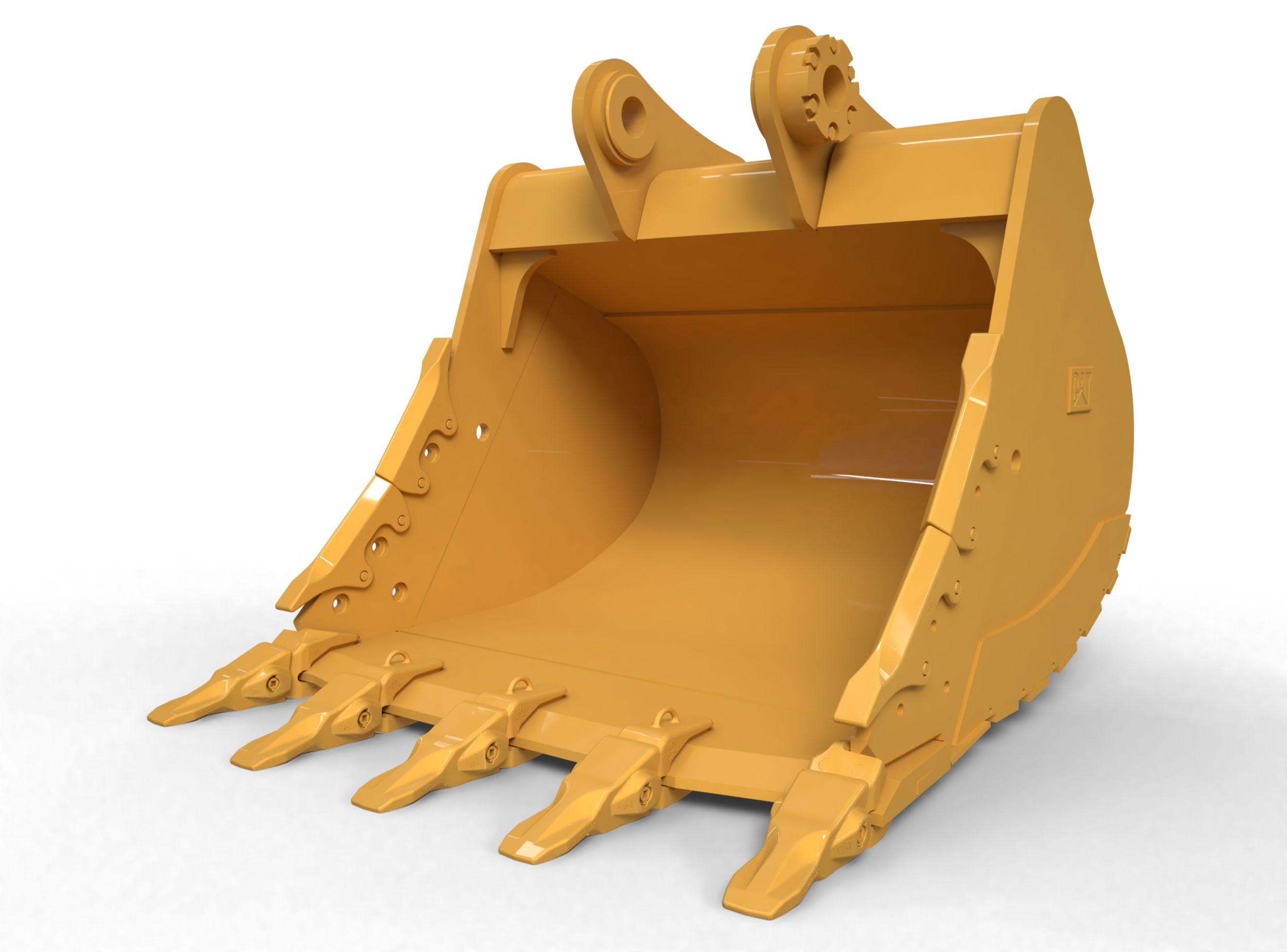

Heavy Duty Bucket 1200 mm (48 in): 550-9543

Heavy Duty Bucket 1050 mm (42 in): 550-9545

Heavy Duty Bucket 1300 mm (852 in): 550-9544

Heavy Duty Bucket 1050 mm (42 in): 550-9585

Heavy Duty Bucket 1200 mm (48 in): 550-9680

Heavy Duty Bucket 1200 mm (48 in): 550-9659

Heavy Duty Bucket 600 mm (24 in): 550-9658

Heavy Duty Bucket 1650 mm (66 in): 541-1779

Heavy Duty Bucket 1350 mm (54 in): 541-1778

Heavy Duty Bucket 1650 mm (66 in): 528-4662

Heavy Duty Bucket 1650 mm (66 in): 528-4664

Heavy Duty Bucket 1850 mm (73 in): 518-9322

Heavy Duty Bucket 1950 mm (77 in): 518-9324

Heavy Duty Bucket 1650 mm (65 in): 518-9321

Heavy Duty Bucket 1850 mm (73 in): 518-9323

Heavy Duty Bucket 1750 mm (69 in): 577-0344

Heavy Duty Bucket 600 mm (24 in): 550-9677

Heavy Duty Bucket 1200 mm (48 in): 550-9656

Heavy Duty Bucket 1200 mm (48 in): 550-9534

Heavy Duty Bucket 1200 mm (48 in): 550-9535

Heavy Duty Bucket 1300 mm (51 in): 550-9678

Heavy Duty Bucket 1300 mm (51 in): 550-9657

Heavy Duty Bucket 1300 mm (852 in): 550-9536

Heavy Duty Bucket 1650 mm (66 in): 528-2204

Heavy Duty Bucket 1850 mm (72 in): 566-6632

Heavy Duty Bucket 1900 mm (74 in): 528-4548

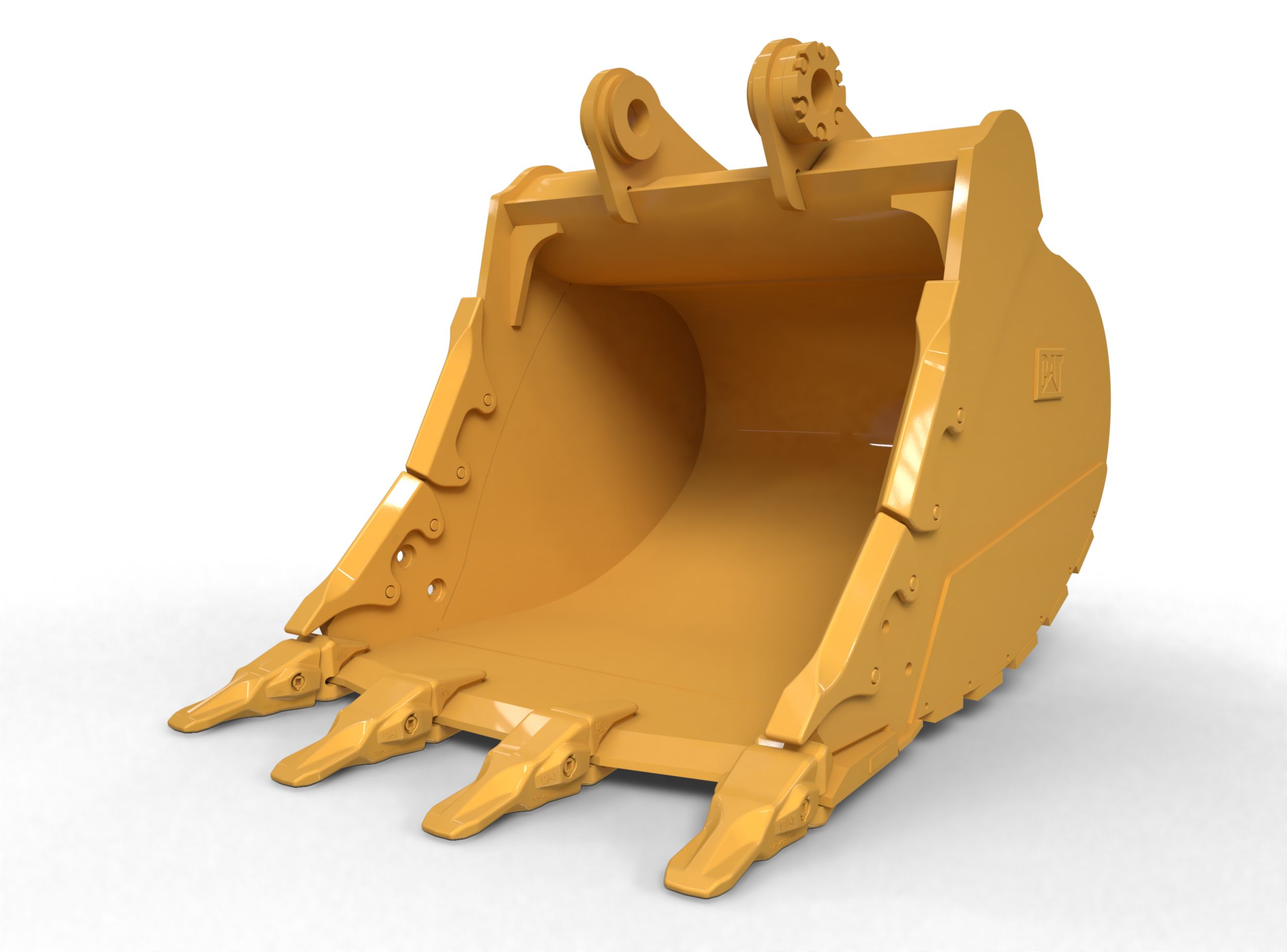

Severe Duty Bucket 1050 mm (42 in): 541-1780

Severe Duty Bucket 1200 mm (47 in): 573-4983

Severe Duty Bucket 1350 mm (54 in): 541-1781

Severe Duty Bucket 1200 mm (48 in): 550-9622

Severe Duty Bucket 1350 mm (54 in): 528-4665

Severe Duty Bucket 1350 mm (54 in): 554-3128

Severe Duty Bucket 1650 mm (66 in): 528-4667

Severe Duty Bucket 1550 mm (61 in): 518-9327

Severe Duty Bucket 1550 mm (61 in): 518-9333

Severe Duty Bucket 1950 mm (77 in): 518-9337

Severe Duty Bucket 1550 mm (61 in): 518-9334

Severe Duty Bucket 1650 mm (65 in): 518-9336

Severe Duty Bucket 1700 mm (67 in): 518-9328

Severe Duty Bucket 1600 mm (64 in): 570-5299

Severe Duty Bucket 1450 mm (59 in): 568-7616

Severe Duty Bucket 1650 mm (66 in): 558-6618

Severe Duty Bucket 1650 mm (66 in): 528-4593

Severe Duty Bucket 1650 mm (65 in): 528-8159

Severe Duty Bucket 1650 mm (65 in): 518-9354

Severe Duty Bucket 1850 mm (73 in): 528-8156

Severe Duty Bucket 1850 mm (73 in): 518-9351

Severe Duty Bucket 1900 mm (75 in): 528-8155

Severe Duty Bucket 1900 mm (75 in): 518-9330

Severe Duty Bucket 1950 mm (77 in): 518-9355

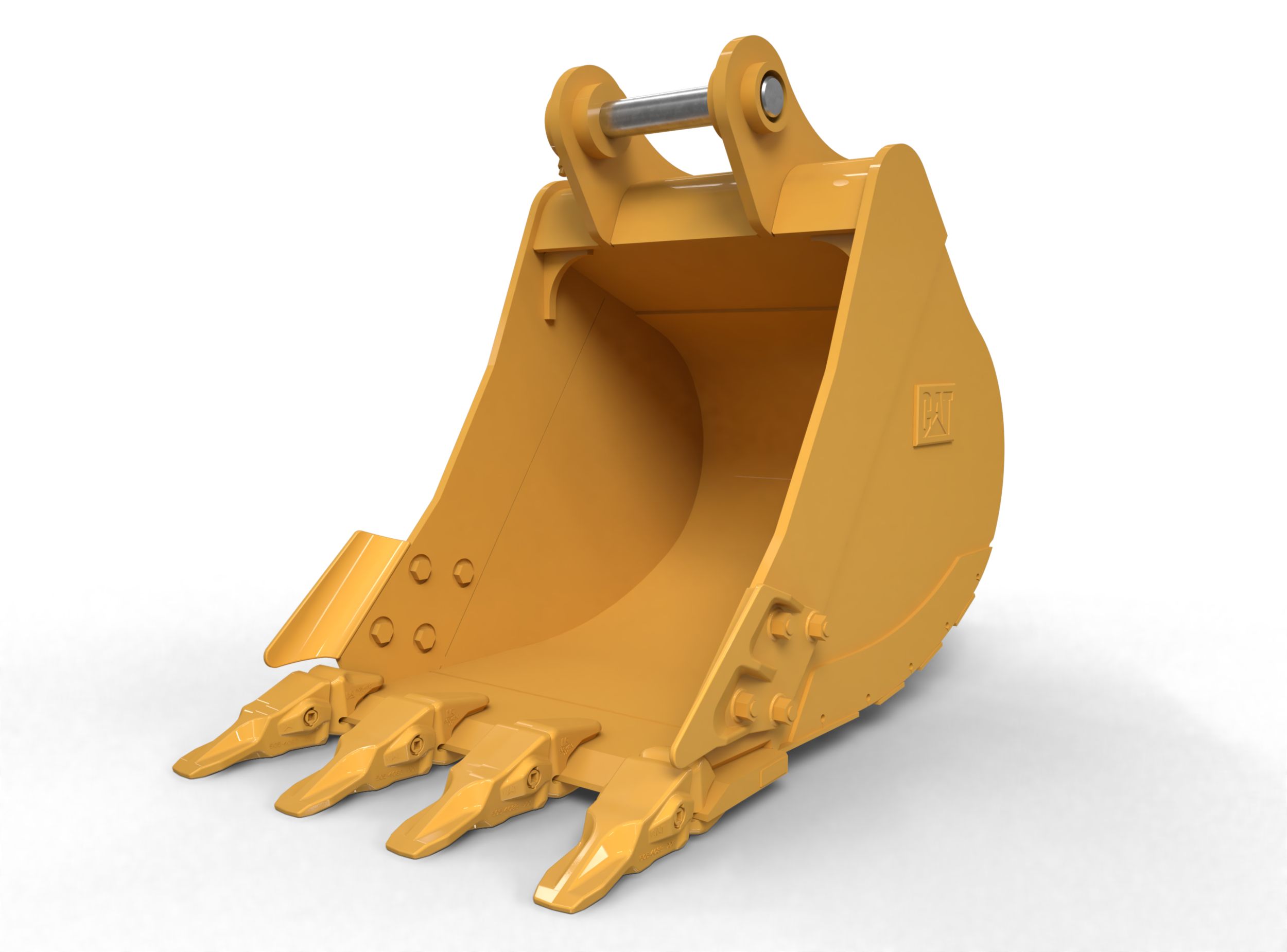

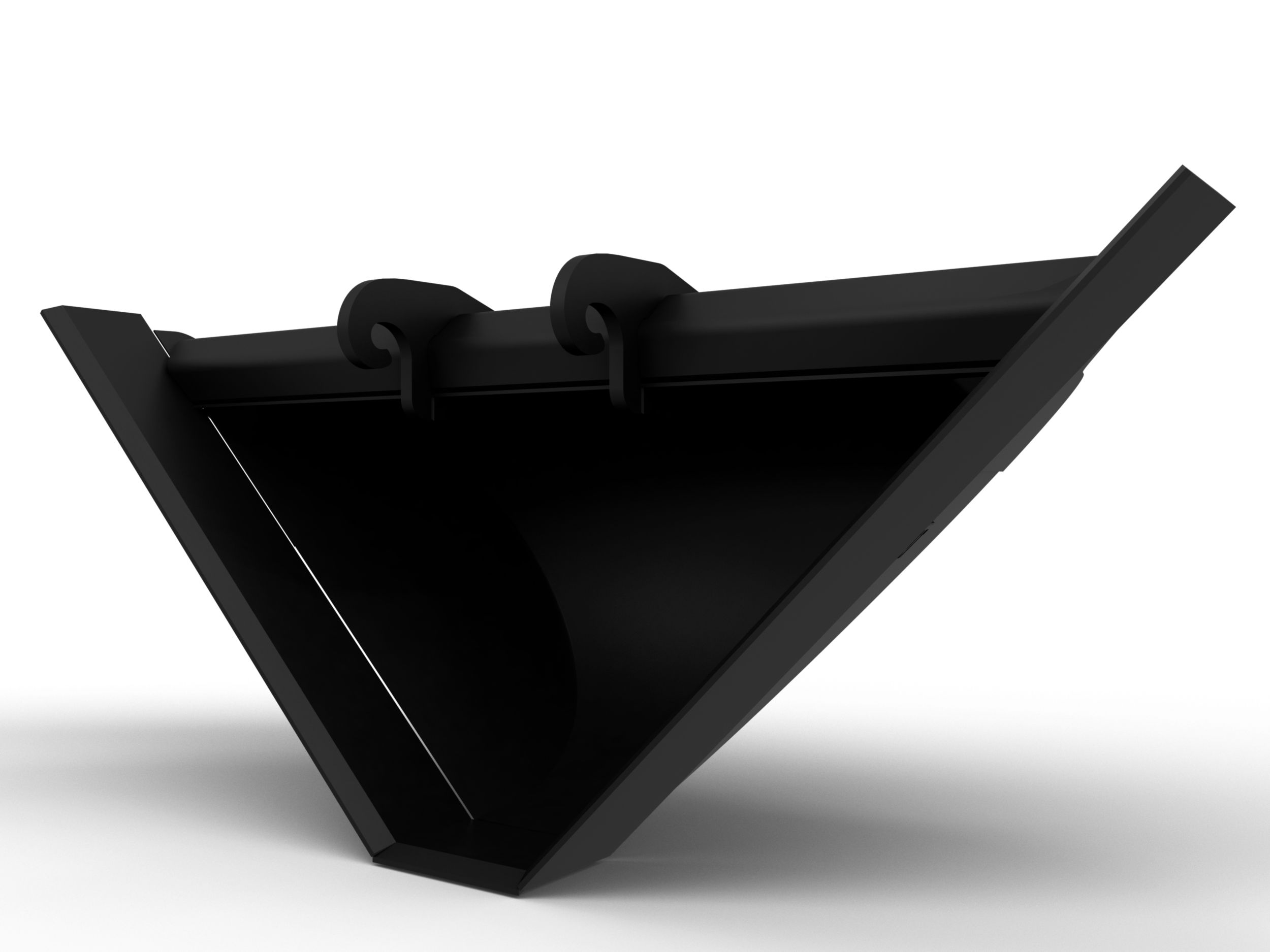

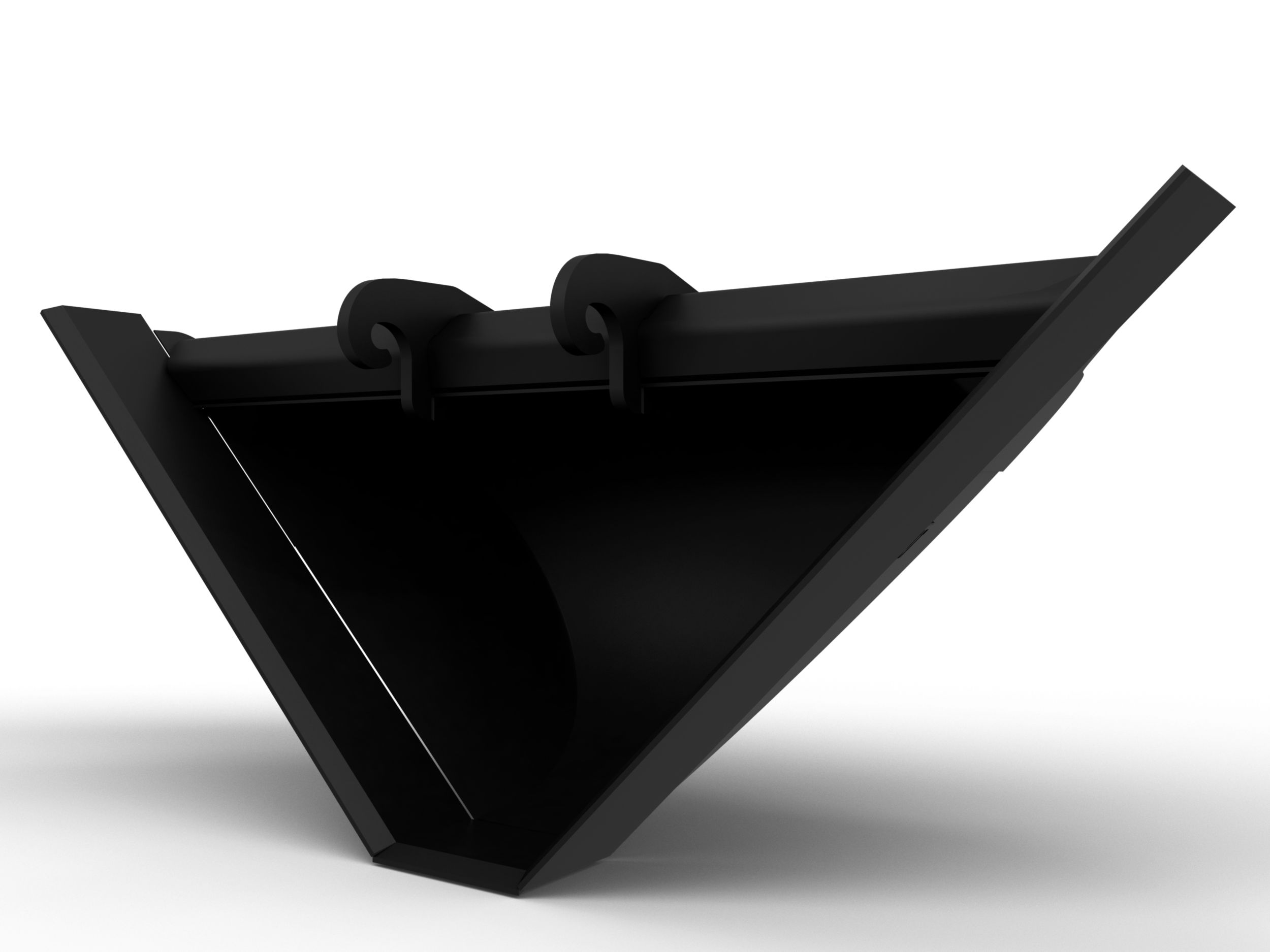

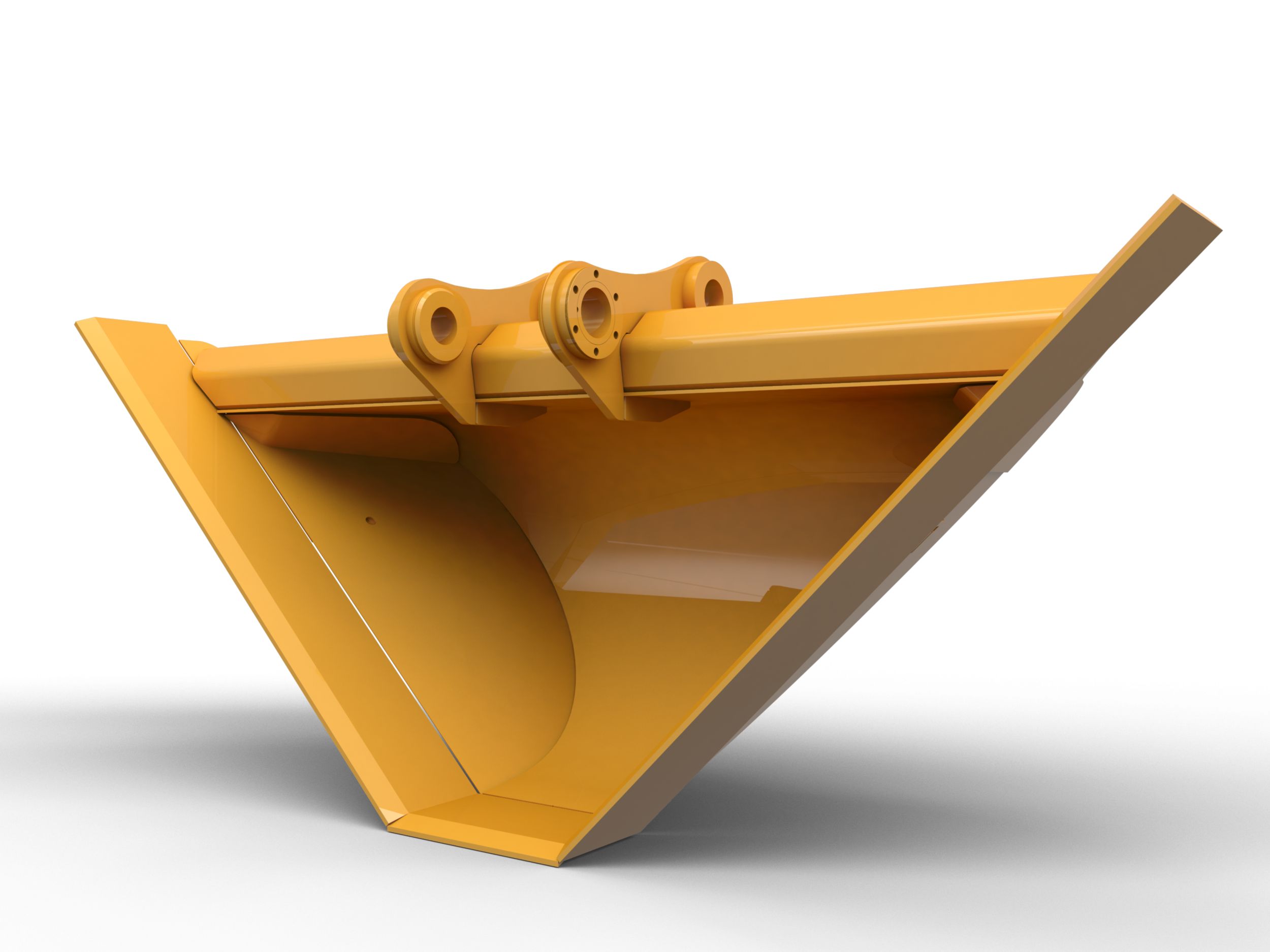

Ditch Cleaning Bucket 2100 mm (83 in): 441-6090

Ditch Cleaning Bucket 2100 mm (83 in): 441-6087

Ditch Cleaning Bucket 2100 mm (83 in): 441-6093

Ditch Cleaning Bucket 1800 mm (72 in): 441-6091

Ditch Cleaning Bucket 1800 mm (72 in): 461-4189

Ditch Cleaning Bucket 1800 mm (72 in): 461-4191

Ditch Cleaning Bucket 2200 mm (87 in): 461-4194

Ditch Cleaning Bucket 2100 mm (83 in): 461-4192

Ditch Cleaning Bucket 1800 mm (71 in): 456-2374

Ditch Cleaning Bucket 1800 mm (72 in): 441-6082

Ditch Cleaning Bucket 2400 mm (94 in): 456-2376

Ditch Cleaning Bucket 2100 mm (83 in): 460-5826

Ditch Cleaning Bucket 2200 mm (87 in): 441-6079

Ditch Cleaning Bucket 1800 mm (72 in): 461-4183

Ditch Cleaning Bucket 2000 mm (78 in): 441-6078

Skeleton - Heavy Duty Bucket 1550 mm (61 in): 523-3397

Grading Bucket 2000 mm (78 in): 512-8405

Grading Bucket 1800 mm (70 in): 512-8404

Grading Bucket 1800 mm (70 in): 514-7844

Grading Bucket 1800 mm (70 in): 514-7843

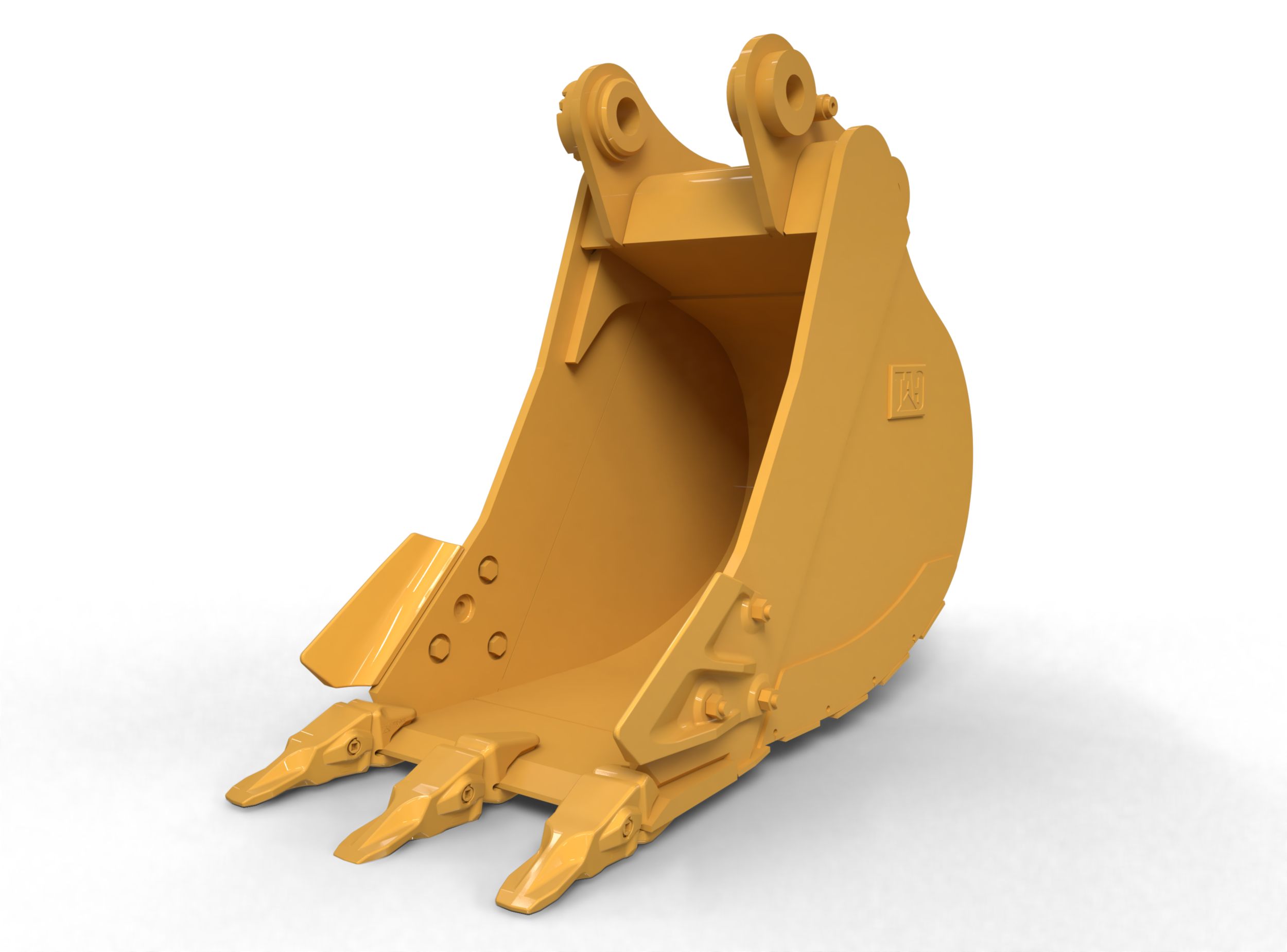

Profile Bucket 300 mm (12 in): 287-5363

Profile Bucket 300 mm (12 in): 326-7404

Profile Bucket 400 mm (16 in): 326-7405

Profile Bucket 500 mm (20 in): 223-1383

Profile Bucket 500 mm (20 in): 214-1022

Profile Bucket 500 mm (20 in): 326-7406

Profile Bucket 500 mm (20 in): 307-6475

Trenching Bucket 600 mm (23 in): 512-8406

Trenching Bucket 600 mm (23 in): 514-7846

Trenching Bucket 660 mm (26 in): 514-7845

Utility Duty Bucket 600 mm (24 in): 550-9426

Utility Duty Bucket 1200 mm (48 in): 186-6740

Utility Duty Bucket 1300 mm (51 in): 226-2146

Utility Duty Bucket 1400 mm (55 in): 226-1674

Utility Duty Bucket 1500 mm (60 in): 550-9427

Utility Duty Bucket 1500 mm (60 in): 226-2141

Utility Duty Bucket 1700 mm (67 in): 226-2142

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 511-5336

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 511-5339

Ditch Cleaning Tilt Bucket 2000 mm (79 in): 511-5340

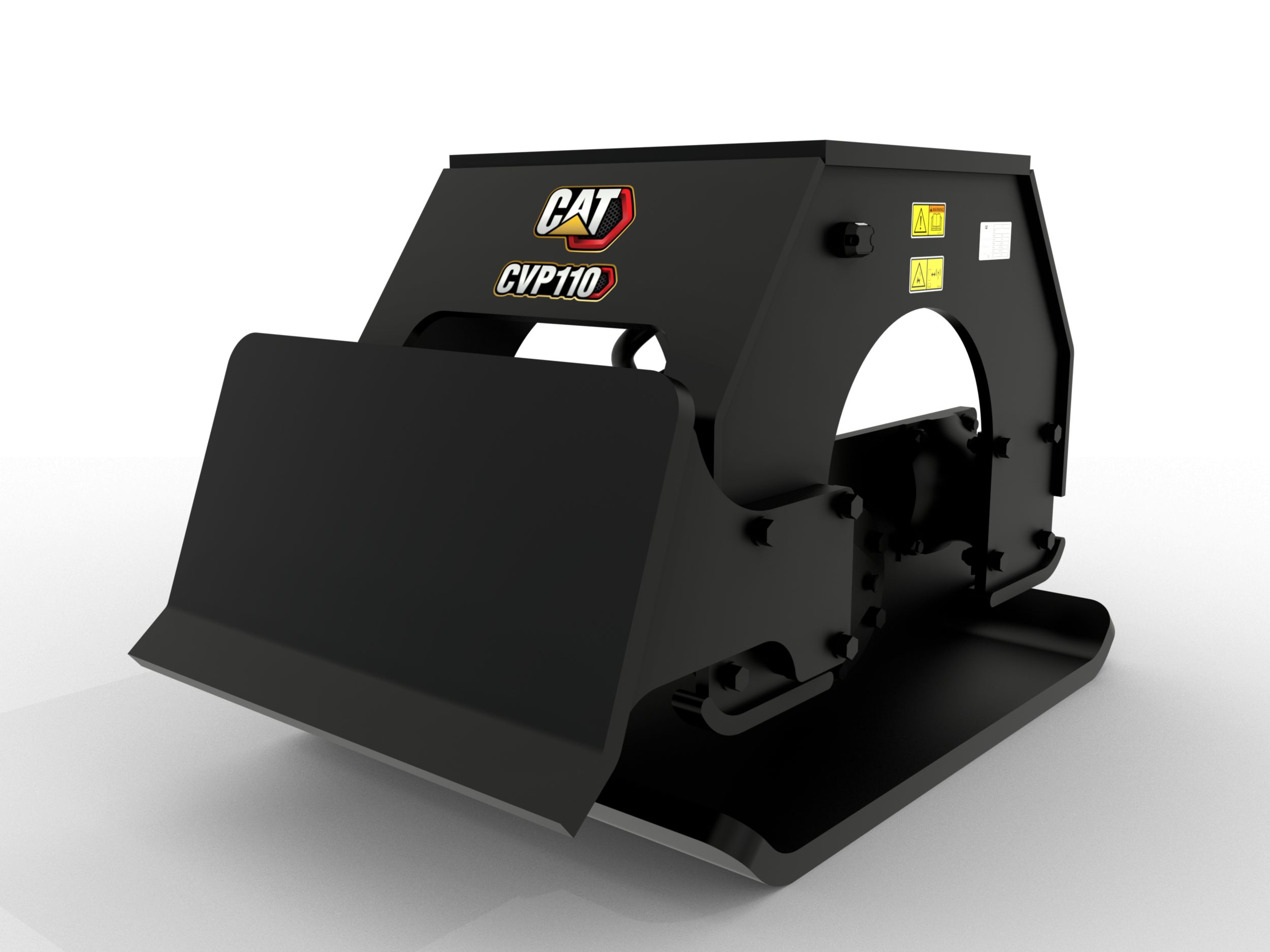

CVP110

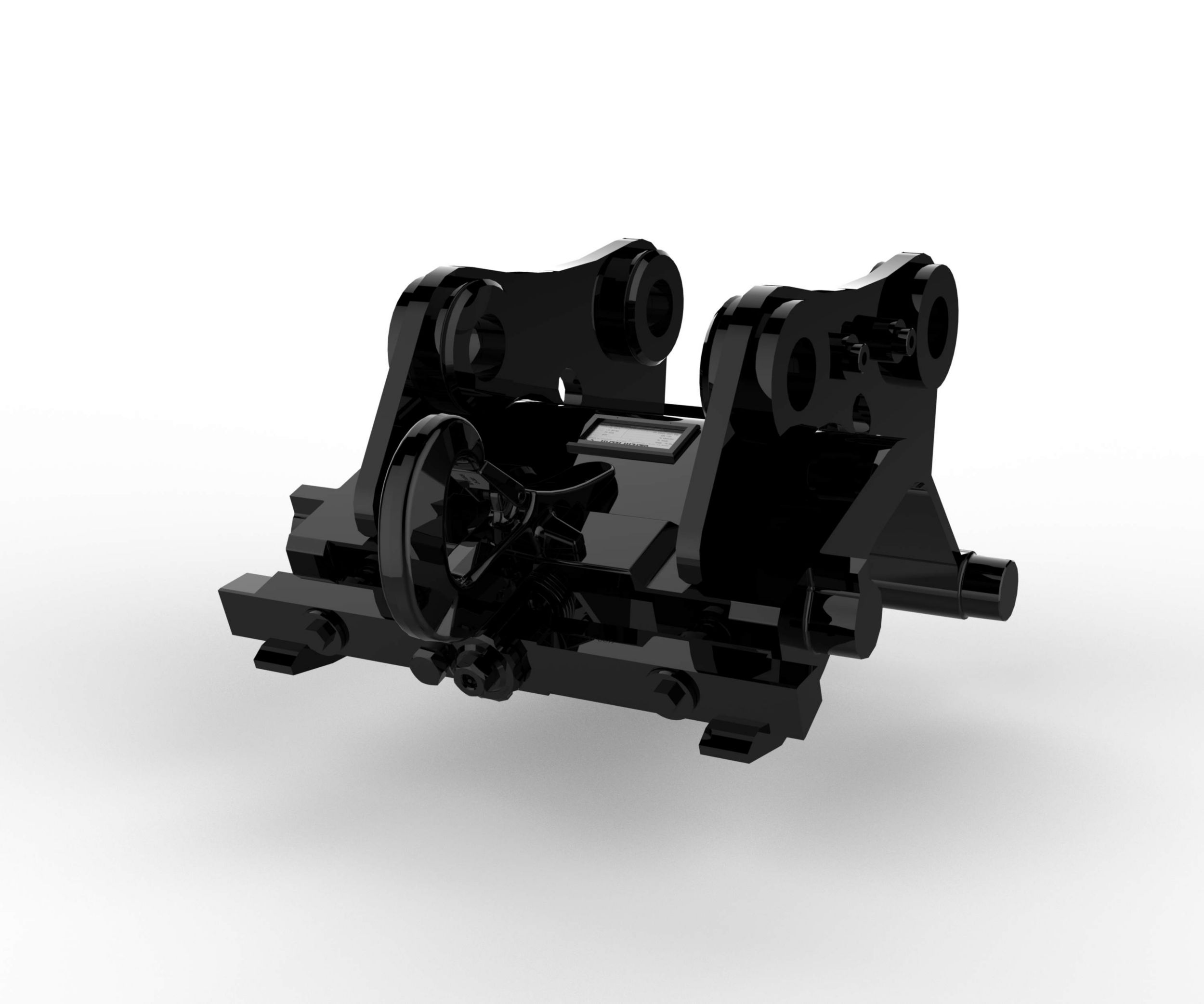

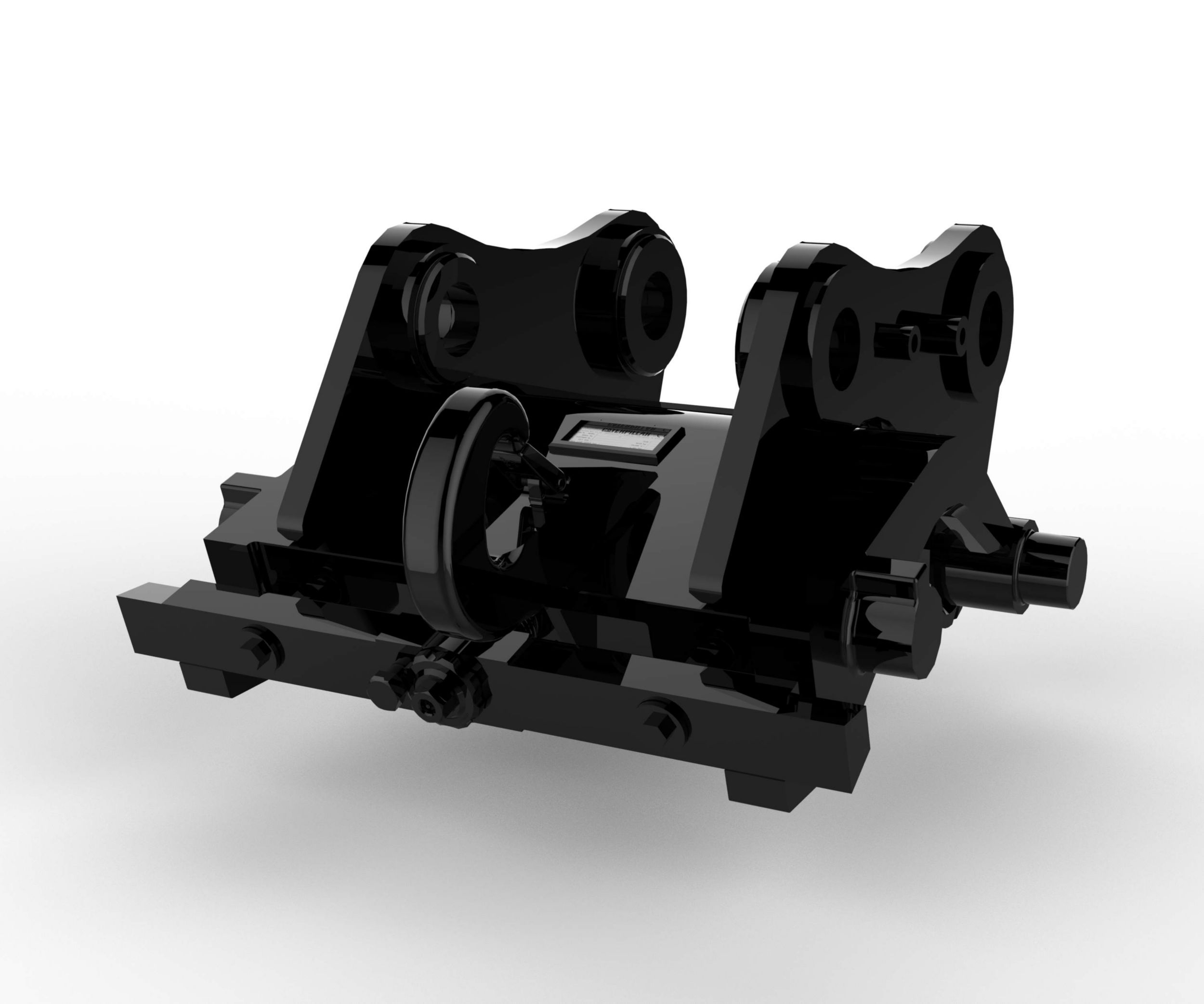

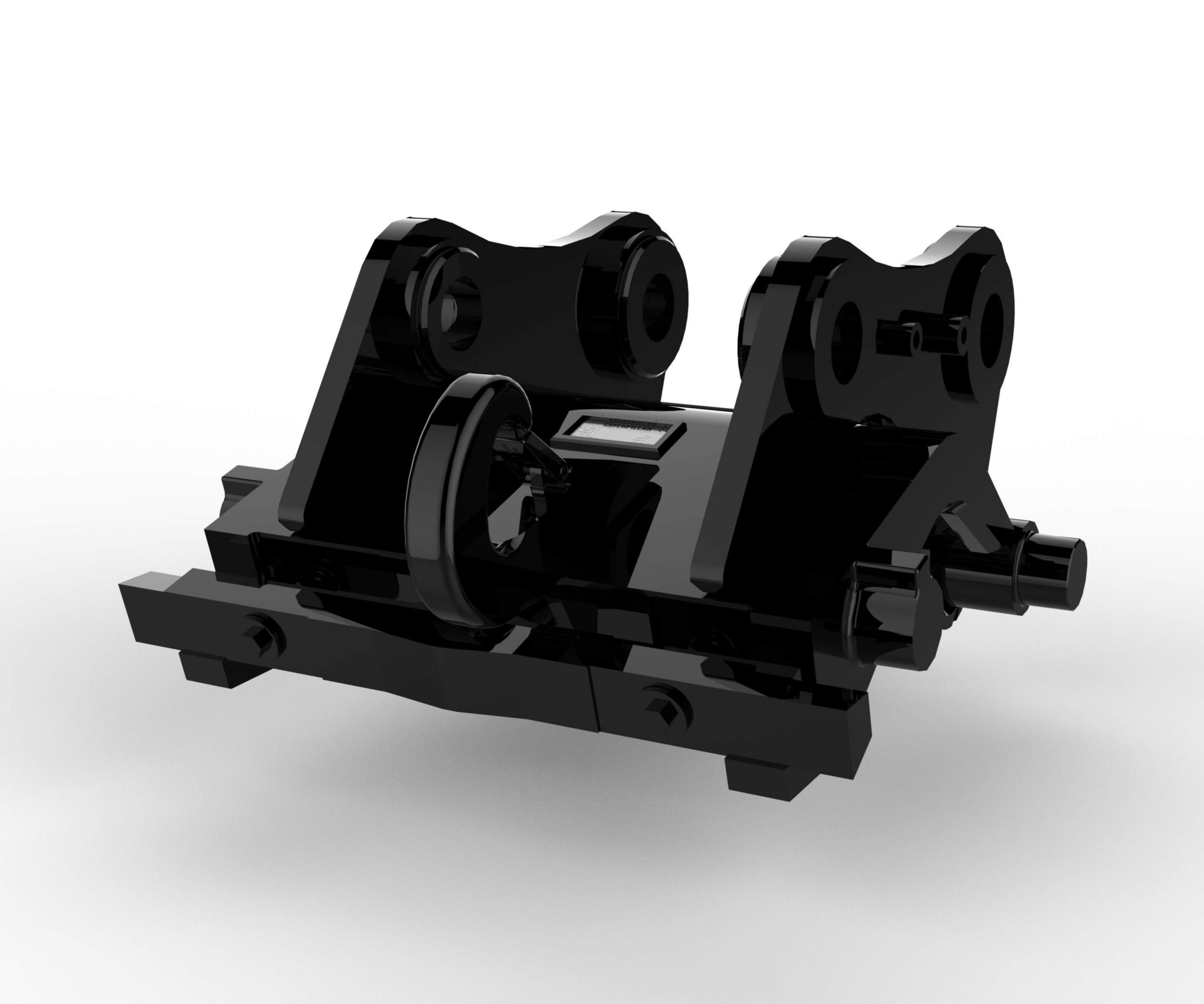

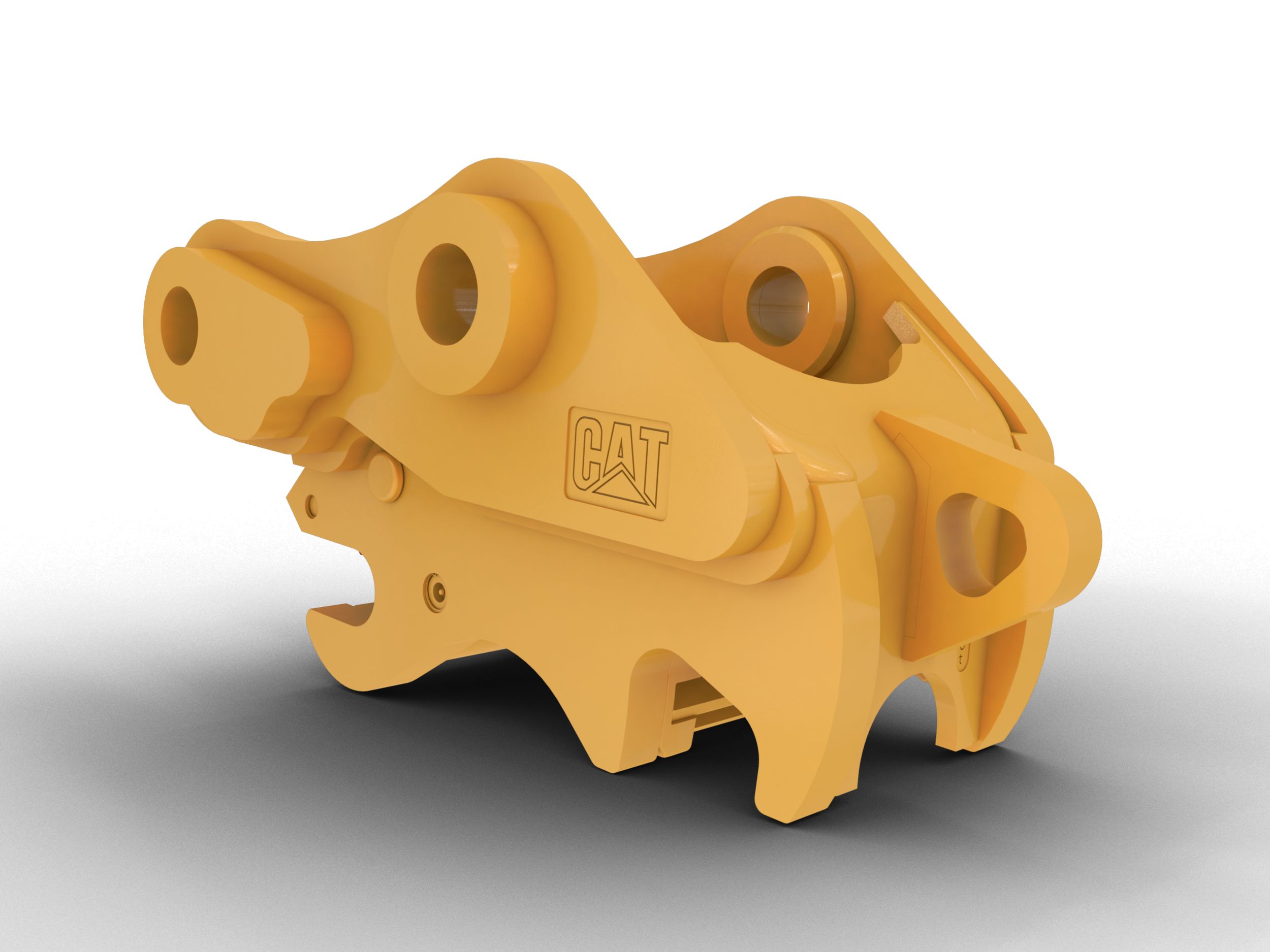

CW-45S

CW-45S

CW-55S

CW-55S

CW-45

CW-55

CW-45

CW-55

Pin Grabber Coupler (B-Linkage): 455-3909

G345 Demolition & Sorting Grapple: 608-0756

G318 WH Demolition & Sorting Grapple: 587-8970

CTV30-1700 Clamshell Grapple

CTV30-1900 Clamshell Grapple

CTV30-2300 Clamshell Grapple

CTV30-2700 Clamshell Grapple

CTV30-2900 Clamshell Grapple

CTV30-3100 Clamshell Grapple

CTV30-1900-BOCE Clamshell Grapple

CTV30-2300-BOCE Clamshell Grapple

CTV30-2500-BOCE Clamshell Grapple

CTV30-2700-BOCE Clamshell Grapple

GSH420 4-Tine, 600-Liter Orange Peel Grapple

GSM50 5-Tine, 1250-Liter Orange Peel Grapple

GSH555 5-Tine, 1000-Liter Orange Peel Grapple

GSH555 5-Tine, 1500-Liter Orange Peel Grapple

GSH455 4-Tine, 1000-Liter Orange Peel Grapple

GSH455 4-Tine, 1500-Liter Orange Peel Grapple

GSH455 4-Tine, 2000-Liter Orange Peel Grapple

H180 GC

H180 GC S

H140 S

H160 S

MP332 Demolition Jaw

MP324 Demolition Jaw

MP332 Pulverizer Jaw

MP324 Universal Jaw

MP345 Pulverizer Jaw

MP324 Pulverizer Jaw

MP345 Concrete Cutter Jaw

MP332 Concrete Cutter Jaw

MP324 Concrete Cutter Jaw

MP332 Shear Jaw

MP345 Shear Jaw

MP324 Secondary Pulverizer Jaw

MP324 Shear Jaw

MP324 Tank Shear

1290mm (51in) Ripper

S3050 Rotating Scrap & Demolition Shear

Cat® Detect with Smart Camera

Cat® Detect with Surround Cameras

G318 Demolition & Sorting Grapple: 587-8966

GSH525 5-Tine, 1150-Liter Orange Peel Grapple

H180 S

MP345 Demolition Jaw

MP332 Tank Shear