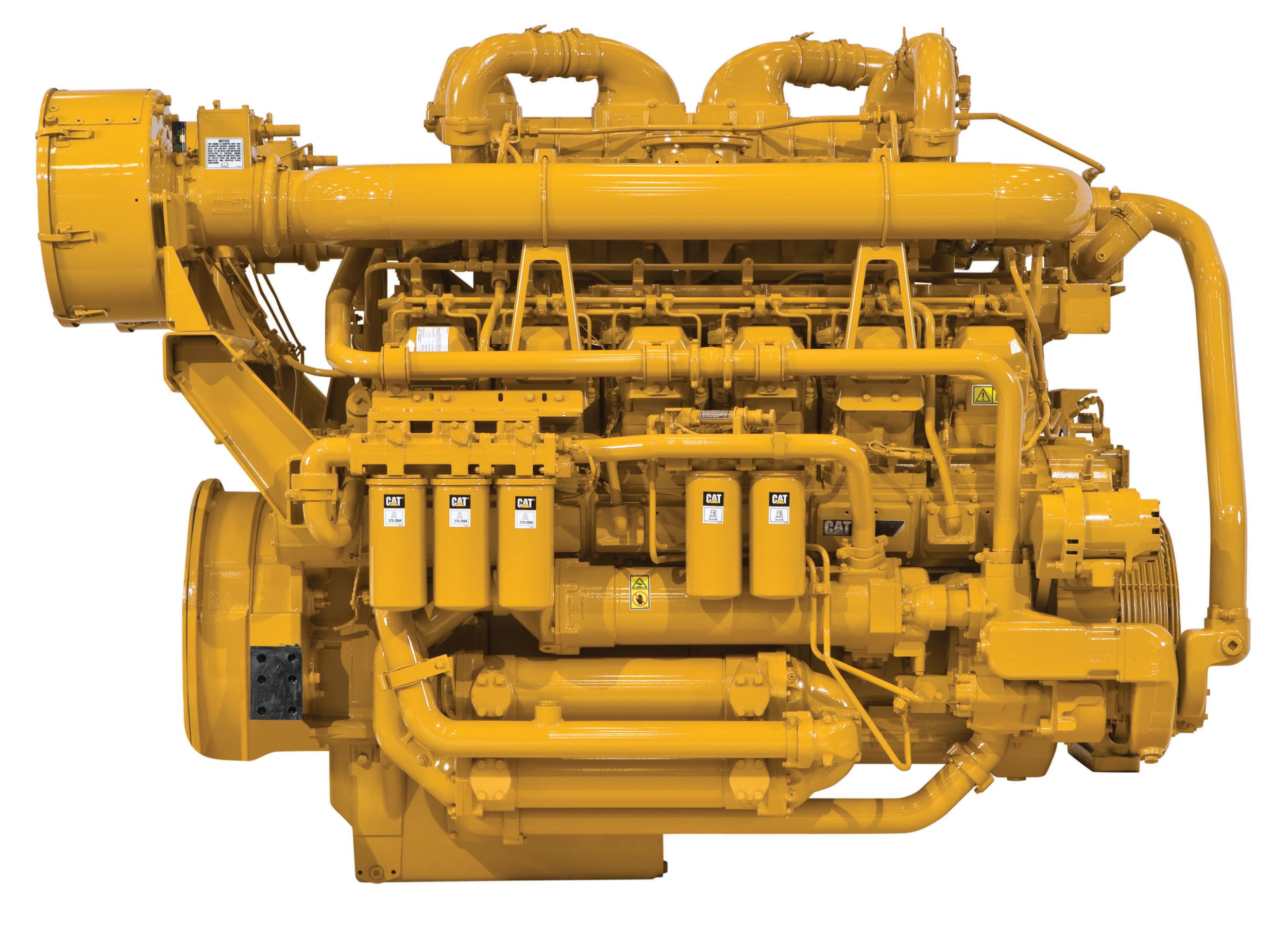

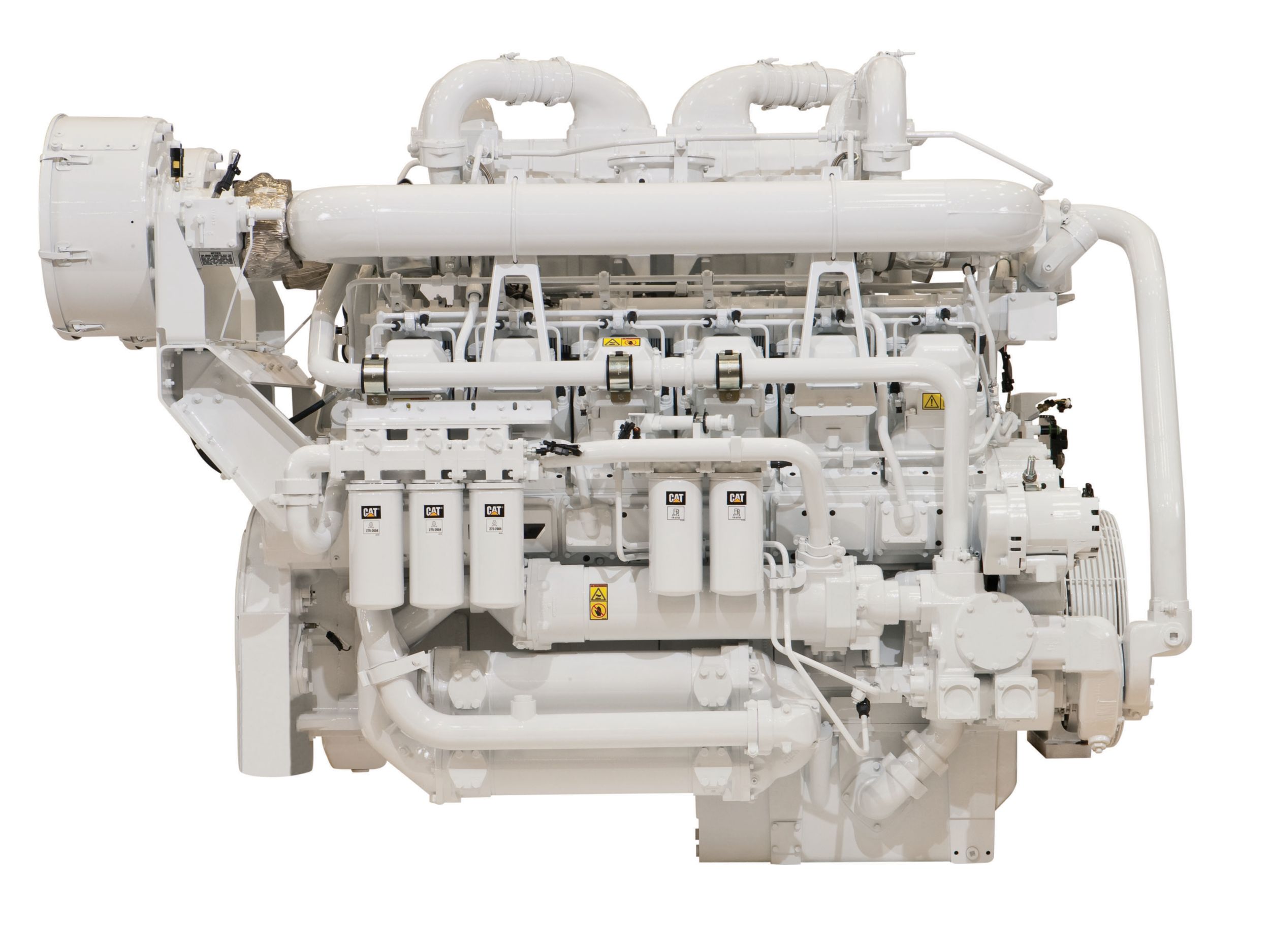

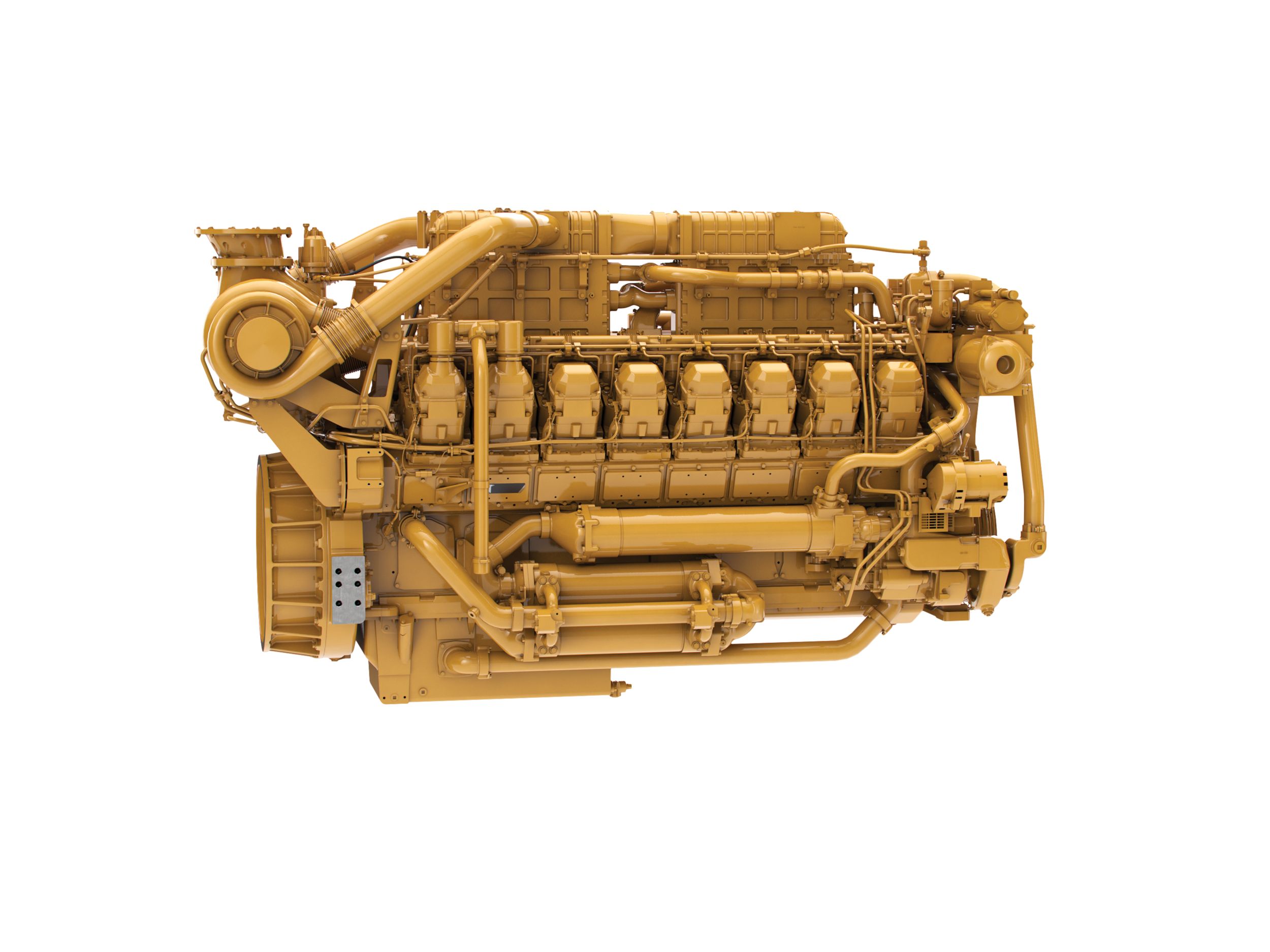

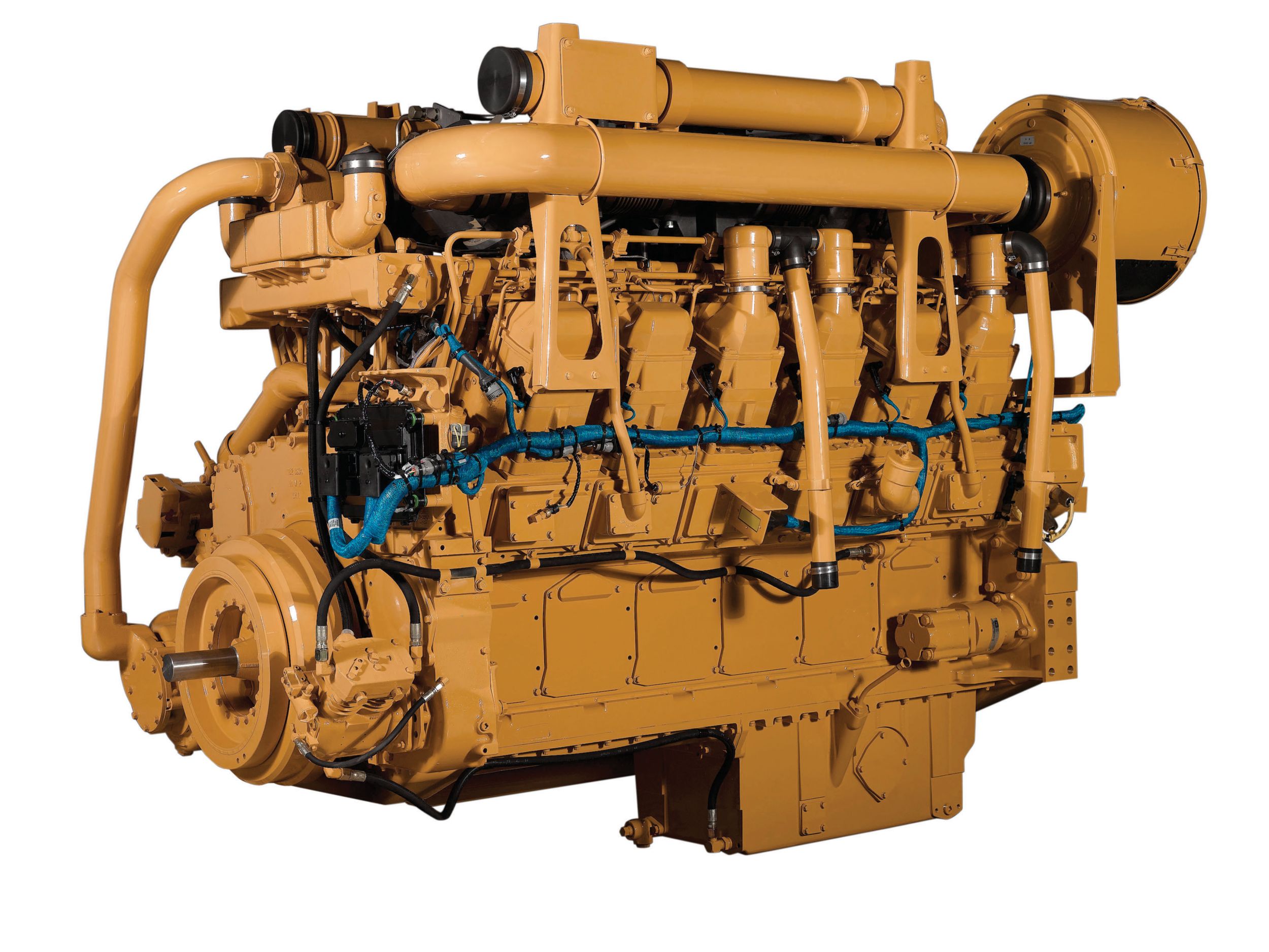

3512C DGB

Well stimulation operations in the oilfield are complex and demanding. The 3512C (HD) with dynamic gas blending engine for well stimulation operations was specifically developed to lower fuel cost while while meeting the highest standards in performance, durability, reliability, and emissions. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. 3512C (HD) engines, with ratings: 1678-1864 bkW (2250-2500 bhp) @ 1900 rpm meet IMO Tier II, U.S. EPA Marine Tier 2, and U.S. EPA Non-road Tier 2 equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Maximum Rating

2500.0 BHP

Displacement

3574.0 in³

Minimum Rating

2150.0 BHP

Specification

Value

Maximum Rating

2500.0 BHP

Displacement

3574.0 in³

Minimum Rating

2150.0 BHP

Aspiration

Turbocharged-Aftercooled

Flywheel and Flywheel Housing

SAE No. 0

Flywheel Teeth

151

Stroke

8.5 in

Bore

6.7 in

Specification

Value

Emissions

Non-current EPA Tier 2

Specification

Value

Length

110.4 in

Width

59.2 in

Height

86.3 in

Weight

14650.0 lb

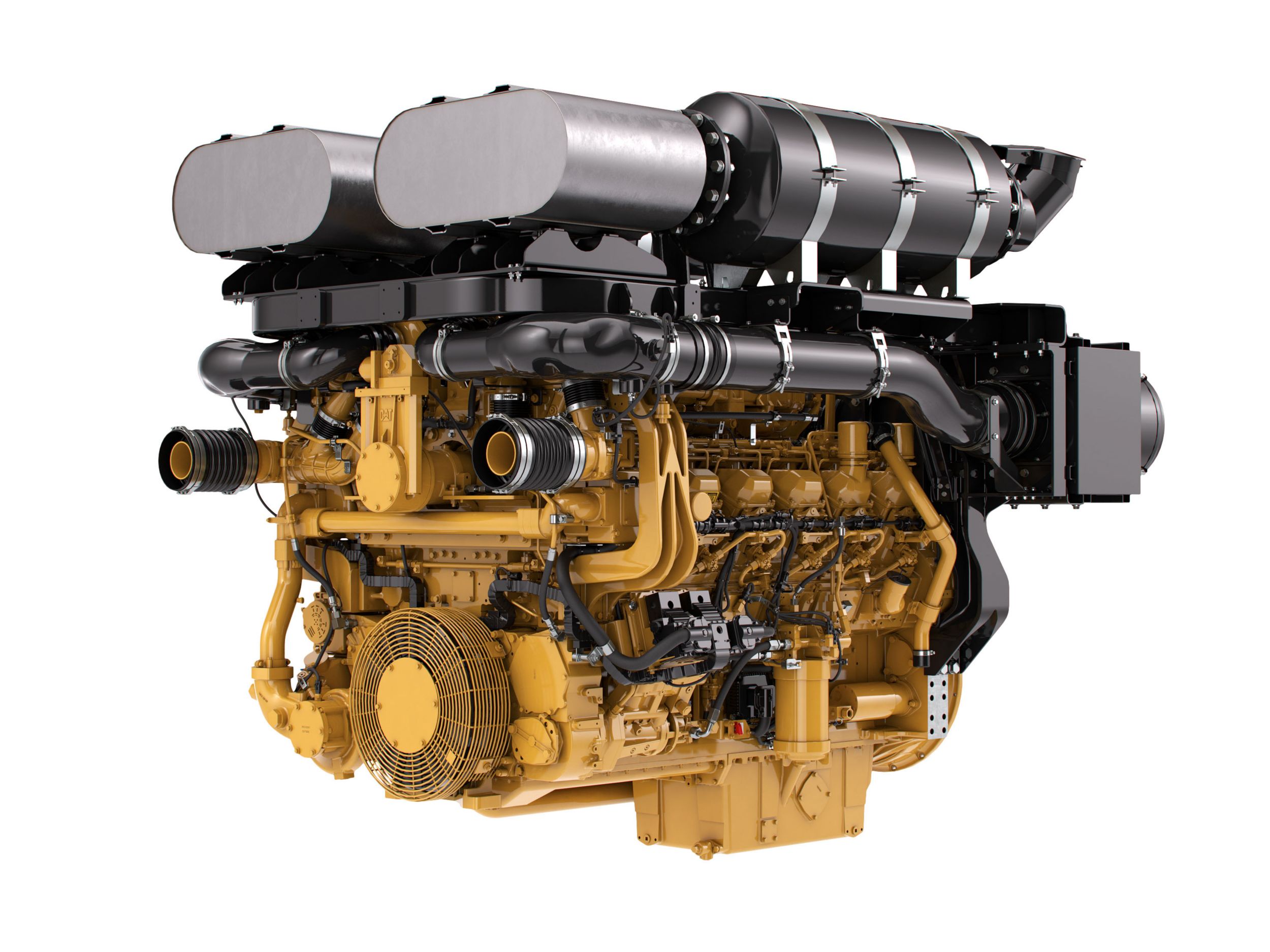

Integration with engine cooling system allows ease of installation and a tighter overall engine package

ADEM A3 engine management system integrates speed control, air/fuel ratio control and ignition/detonation controls into a complete engine management system with integrated digital ignition, engine protection and monitoring

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Large variety of factory-installed engine attachments reduces packaging time

Every engine is full-load tested to ensure proper engine performance

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your petroleum engine - Cat parts and labor warranty - Preventive maintenance agreements available for repair-before-failure options - S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: • Internal engine component condition • Presence of unwanted fluids • Presence of combustion by-products • Site-specific oil change interval

- Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products. • Cast engine blocks, heads, cylinder liners, front and flywheel housings • Machine critical components • Assemble complete engine

For all your petroleum power requirements, visit www.catoilandgasinfo.com.

For all your petroleum power requirements, visit www.catoilandgasinfo.com.