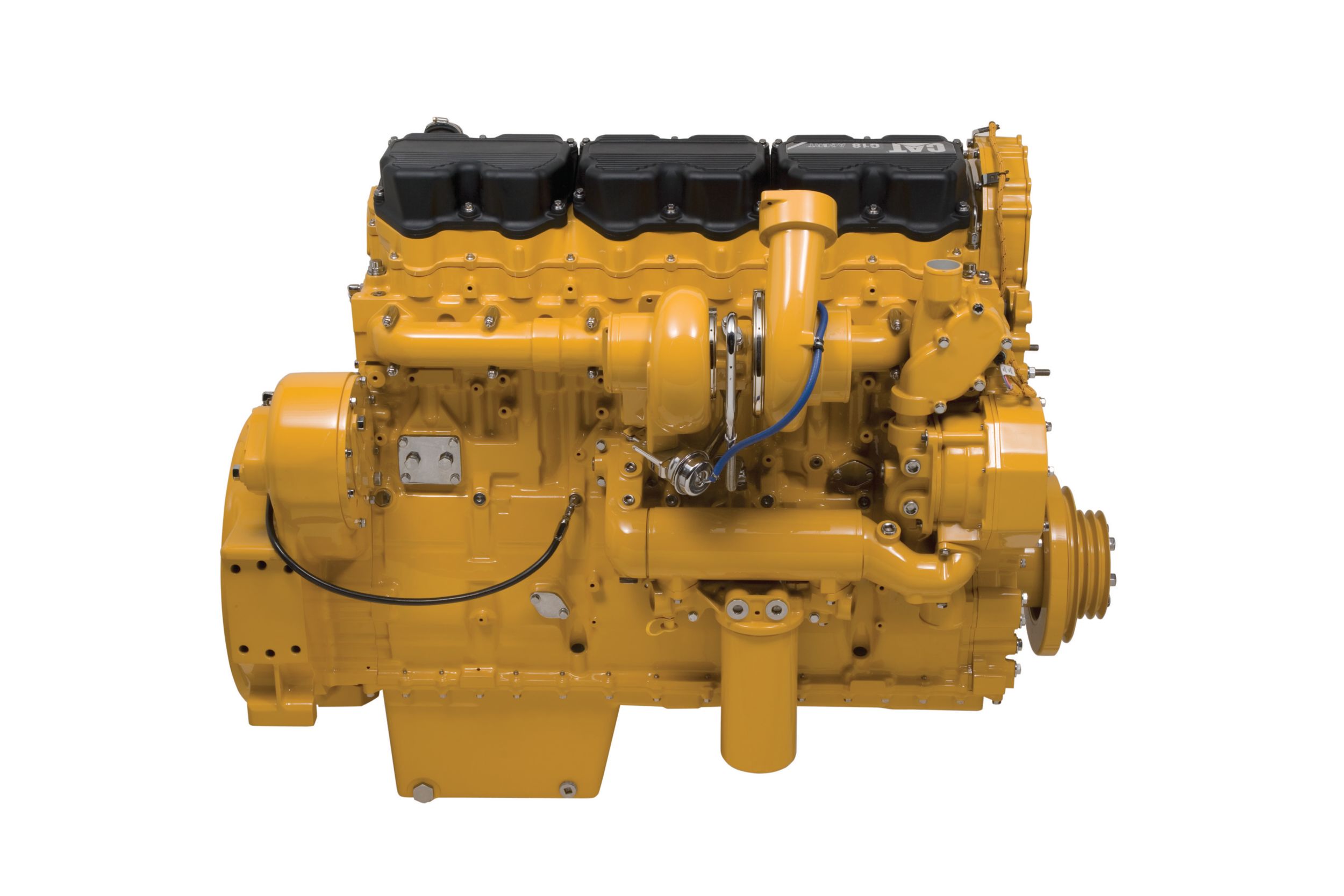

C18 ACERT™

Cat C18 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C18 ACERT engines to deliver excellent performance with low operating costs and emissions.This is an ideal engine for land mechanical drilling applications such as mud pump drives.Cat C18 ACERT™ Industrial Diesel Engine. Ratings: 429-522 bkW (575-700 bhp) @ 1800-2100 rpm meet China Stage II, U.S. EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. Ratings: 570-597 bkW (765-800 bhp) @ 1800-2100 rpm meet U.S. EPA Tier 2 equivalent emission standards.

Maximum Rating

800.0 BHP

Emissions

EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA

Displacement

1100.0 in³

Specification

Value

Maximum Rating

800.0 BHP

Emissions

EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA

Displacement

1100.0 in³

Minimum Rating

575.0 BHP

Bore

5.71 in

Stroke

7.2 in

Rated Speed

2100.0 r/min

Aspiration

Turbocharged-Aftercooled

Governor and Protection

ADEM A3

Engine Weight - Net Dry

2807.0 lb

Rotation from Flywheel End

Counterclockwise

Oil Change Interval

250

Flywheel and Flywheel Housing

SAE No. 0 or SAE No. 1

Flywheel Teeth

136 (SAE 0), 113 (SAE 1)

Specification

Value

Minimum Cooling System - Engine Only

13.2 gal (US)

Specification

Value

Length

54.7 in

Width

36.2 in

Height

49.5 in

- Proven reliability and durability- Robust diesel strength design prolongs life and lowersowning and operating costs- Broad operating speed range- High power density — lightweight engine for weightsensitive applications- PTO drive options provide flexible access to auxiliarypower for pumps and other needs

ADEM A3 control system providing integrated ignition,speed governing, protection, and controls, includingdetonation-sensitive variable ignition timing. ADEM A3has improved: user interface, display system, shutdowncontrols, and system diagnostics.

- Engine-Mounted Transmission Oil Cooler — integration with engine cooling system allows ease ofinstallation and a tighter overall engine package- Engine Brakes — braking capabilities for mobileapplications

For any petroleum application, trust Caterpillar to meetyour exact needs with a factory custom package. Cat®engines, generators, enclosures, controls, radiators,transmissions — anything your project requires — can becustom designed and matched to create a one-of-a kindsolution. Custom packages are globally supported andare covered by a one-year warranty after startup.

Caterpillar has a full line of engine-transmission packagesthat can be fully integrated with your axle, hydraulics, andoperator interface. Cat transmissions deliver continuousoperation under full load, smooth shifting at any speed,and maximum up time, with unmatched durability andeasy maintenance.

Large variety of factory-installed engine attachmentsreduces packaging time

Every engine is full-load tested to ensure proper engineperformance.

- More than 2,200 dealer outlets- Cat factory-trained dealer technicians service everyaspect of your petroleum engine- Cat parts and labor warranty- Preventive maintenance agreements available for repairbefore-failure options- S•O•SSM program matches your oil and coolant samplesagainst Caterpillar set standards

Ownership of these manufacturing processes enablesCaterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheelhousings- Machine critical components- Assemble complete engine

For all your petroleum power requirements, visit www.catoilandgasinfo.com