796 AC

The Cat® 796 AC electric drive truck offers more flexibility than any other truck in its size class — delivering optimized performance and better productivity. Built on a proven truck architecture and high strength structures, the 796 AC delivers a nominal target payload of up to 327 tonnes (360 tons) regardless of attachments. Add in a proven drive system with industry-leading serviceability, and the 796 AC mining truck delivers a hauling solution you can depend on — resulting in high reliability, high availability, and low lifecycle costs. By hauling more every load, every cycle and every shift, it creates a low-cost-per-ton hauling operation that delivers a better bottom line.

Gross Power - SAE J1995

3500 HP

Engine Model

Cat® C175-16

Net Power - SAE J1349

3405 HP

Specification

Value

Gross Power - SAE J1995

3500 HP

Engine Model

Cat® C175-16

Net Power - SAE J1349

3405 HP

Rated Speed

1800 r/min

Emissions Rating

Fuel Optimized

Bore

6.9 in

Stroke

8.7 in

Displacement

5187 in³

Note (1)

Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator.

Note (2)

U.S. EPA Tier 4 Final / EU Stage V available for applicable markets.

Note (3)

Additional fuel optimized selectable power ratings: 2312 kW / 3,100 hp

Specification

Value

Rated Gross Machine Weight

1270000 lb

Chassis Weight

448415 lb

Body Weight Range

38 833 – 42 907 kg (85,611 – 94,594 lb)

Note (1)

Consult your tire manufacturer for maximum tire load.

Note (2)

Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires.

Note (3)

Refer to Cat Mining Truck 10/10/20 Overload Policy (AEXQ0250) for maximum gross machine weight limitations

Nominal Rated Payload

360 ton (US)

Specification

Value

Front Axle - Empty

47 %

Rear Axle - Empty

53 %

Front Axle - Loaded

33 %

Rear Axle - Loaded

67 %

Note

Weight distributions optimized with Cat body.

Specification

Value

Total Reduction Ratio

35:01:00

Top Speed - Loaded

40 mile/h

Generator/Alternator

Cat brushless, engine mounted, dual bearing

Controls

Cat IGBT Inverter Technology, air cooled, pressurized cabinet with filtration

Wheel Motor

Cat AC induction, rear axle mounted

Cooling System

Cat variable speed, hydraulically driven cooling system

Specification

Value

Standard Tires

59/80 R63

Rims

44" x 63"

Note (1)

Quick Change Rims optional.

Note (2)

Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection and TKPH (TMPH) capabilities.

Specification

Value

Service Brakes

Four-Corner, Wet Disc, Oil Cooled, Hydraulically Actuated

Front Wet Disc Brake Surface Area

20378 in²

Rear - Wet Disc Brake Surface Area

30750 in²

Standards

Service and Secondary: ISO 3450:2011

Parking Brake

Four-corner, Multi-disc, Spring Applied, Hydraulically Released

Load Brake

Rear service brakes

Dynamic Retarding Power - Continuous

5480 HP

Note

Anti-Lock Brake System (ABS) optional with CMD package

Specification

Value

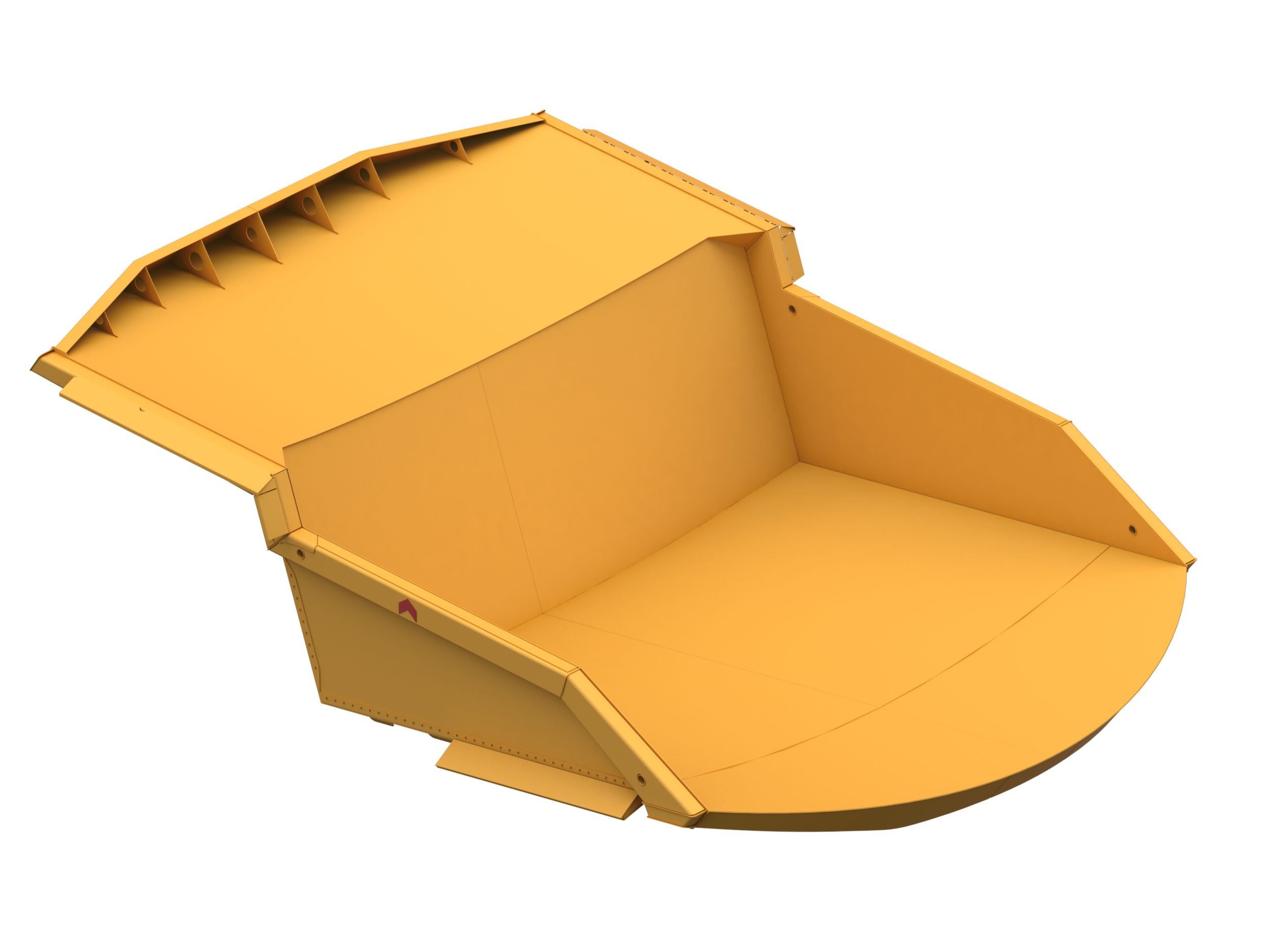

Struck

97-153 m³ (127-200 yd³)

Heaped (SAE 2:1)

186-237 m³ (243-310 yd³)

Note

Consult your local Cat dealer for body recommendations.

Specification

Value

Type

Twin, two-stage hydraulic cylinders with snubbing valve.

Pump Flow - High Idle

257.3 gal/min

Relief Valve Setting - Raise

3029 psi

Body Raise Time - High Idle

21 s

Body Lower Time - Float

22 s

Body Power Down- High Idle

17.5 s

Note (1)

Twin, two-stage hydraulic cylinders mounted outside main frame; double-acting cylinders in both stages.

Note (2)

Power raise in both stages; power down capability in both stages.

Note (3)

Automatic body-lower modulation reduces impact on frame.

Specification

Value

Type

Self-contained nitrogen/oil cylinders, pin-to-pin mounting, top & bottom double shear clevis attachments

Effective Cylinder Stroke - Front

4 in

Effective Cylinder Stroke - Rear

2 in

Rear axle - Oscillation

+/- 5.32 degrees

Specification

Value

Fuel Tank

1300 gal (US)

Fuel Tank (Tier 4)

1200 gal (US)

Diesel Exhaust Fluid Tank

100 gal (US)

Cooling System

211 gal (US)

Crankcase

82 gal (US)

Front Wheels - Each

7 gal (US)

Final Drive - Each

67 gal (US)

Hydraulic Tank

296 gal (US)

Hydraulic System - Including Tank

385 gal (US)

Grease Tank

90 lb

Note (1)

DEF Tank only available for U.S. EPA Tier 4 Final / EU Stage V engine option

Specification

Value

Air Conditioning

HFC - 134A refrigerant: 21,600 Btu/h

Heater / Defroster

24600 Btu/h

Note

Ambient capabilities down to -15C (5F) for heater/defroster and up to 50C (122F) for air conditioning.

ROPS Standards (1)

The operator sound pressure level, 75 dB(A), measured according to ISO 6394:2008 and ISO 6396:2008.

ROPS Standards (2)

ROPS (Rollover Protective Structure) meets ISO 3471:2008 for Operator and ISO 13459:2012 for Trainer.

FOPS Standards

FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II for Operator and ISO 13459:2012 Level II for Trainer.

Specification

Value

Steer Angle

39 °

Turning Diameter - Front

106.3 ft

Steering Standards

Steering Standards: ISO 5010:2007

Note

Turning Diameter (ISO 7457:1997)

Specification

Value

Height - Top of ROPS

22.05 ft

Overall Length

51.44 ft

Wheel Base

21.9 ft

Rear Axle - Tail

16.07 ft

Dump Clearance - Empty

5.72 ft

Loading Height - Empty

23.85 ft

Overall Height - Body Raised

48.85 ft

Centerline Front Tire Width

23.06 ft

Front Axle Clearance - Loaded

2.81 ft

Overall Canopy Width (with rock deflectors)

33.15 ft

Outside Body/Canopy Width (without rock deflectors)

31.62 ft

Inside Body Width

29.44 ft

Front Canopy Height - Empty

26.01 ft

Rear Axle Clearance - Loaded

2.8 ft

Centerline of Rear Dual Tire Width

19.5 ft

Overall Tire Width - Empty

30.27 ft

Note

Dimensions listed includes canopy deflectors

- Greater visibility thanks to wide field of view from the cab and radial retard grid that improves right-hand view.

- Safer access and egress with 600-mm-wide (23.6-in-wide) ladders, flat deck, toe kicks, and optional power access stair attachment.

- Confidence-building features such as anti-rollback, traction controls, reverse shift inhibitor, Automatic Retarding Control, and door sensor warning for park brake application.

- Full dynamic retarding through a compact radial grid, backstopped by the proven design of Caterpillar four-corner oil-cooled brakes, for stable handling and confident stopping.

- Fully independent secondary brake system that provides emergency controllability with a hydraulically actuated secondary brake pedal that serves as a backup to electronic controls.

- Achieves a true class-leading 327-tonne (360-ton) payload regardless of local attachments.

- Ease of operation and reduced costs thanks to deep integration of Cat engine, AC drive system, hydraulics and controls.

- End-to-end visibility of all truck parameters for optimized fuel efficiency, speed on grade and parasitic loads across the operating range.

- Excellent slow speed control within service areas as well as superior motor torque and acceleration pulling away from the shovel.

- Ergonomic cab layout, excellent all-around visibility, and controls, levers and switches that are positioned for ease of use.

- Automatic climate control and reduced vibration and sound.

- Next generation seat with height adjuster, adjustable shoulder stock to keep the seatbelt from rubbing, and seat back, side and lumbar bolsters to increase stability.

- High displacement, low rpm rating and conservative horsepower ratings, which mean more time on the haul road and less time in the shop.

- Inlet manifolds and turbochargers that are located outside of the engine's V, giving the service technicians more space to work on top of the engine and within the engine bay.

- Engine and dual bearing drive alternator that can be serviced separately, eliminating shimming.

- Sealed and pressurized inverter cabinet that requires no cleaning, eliminating recurring maintenance.

- Engine walkways and service platforms, modular components and ground-level grouped service points.

- First overhaul life of 25,000 hours for lower cost of ownership, with proven C175 engine and electric drive system.

- Highly validated and proven straight frame rail design that eliminates the bends and breaks that can occur at stress concentrations.

- Outstanding durability delivered by box section construction that uses Caterpillar proprietary steel specification for excellent welding characteristics.

- Increased frame life thanks to deep section main rails in critical areas of the frame lower stress levels.

- Frame, powertrain, engine and components that are built to be rebuilt — delivering multiple lives of like-new performance at a fraction-of-new price.

- Reduced operating costs thanks to the integrated engine and powertrain 100% designed, validated and built by Caterpillar.

- High voltage system that operates at lower current than most competitive trucks, contributing to higher efficiency, lower heat generation, smaller and lighter components, and longer component life.

- Radial style retarding grid with AC electric motor that requires no regular motor maintenance and is quieter and lighter than box grids.

- AC Drive dynamic retarding for continuous retarding power; AC electric motor that reduces maintenance; and state-of-the-art high voltage IGBTs for maximum AC drive system efficiency.

- Variable hydraulic blower fan, which provides optimized cooling even at idle for increased component performance and life.

- Designed to use less fuel, which reduces engine emissions and carbon footprint.

- Optional U.S. EPA Tier 4 Final / EU Stage V engine, which reduces NOx by 62% and particulates by 93% when compared to Tier 1 emissions.

- Reduced waste thanks to Centrifugal Oil Filter (COF), standard self-cleaning engine filter, extended oil change intervals and reduced oil usage.

- Engines compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels, plus power options like trolley.

- Cat Rebuild and Cat Reman programs, which preserve raw materials, conserve energy and reduce emissions.

- Equipped with standard Product Link™ Elite monitoring system, which delivers health and payload information to keep performance high and enable proactive maintenance planning.

- Factory-ready for fully integrated Cat MineStar™ Command for hauling, an autonomous hauling solution proven to increase productivity up to 30%.

- Optional MineStar Fleet, a fleet monitoring system, to measure, manage and maximize the overall hauling operation.

- Optional MineStar Detect proximity detection system, which uses cameras to give operators a better view of what's happening around their equipment.

- Optional in-cab Cat Driver Safety System (DSS) intervenes when operator fatigue or distraction are detected.

- Bodies designed to fit with the chassis, sized to meet payload requirements and work as part of the truck system.

- High Efficiency (HE) dump body option that is lightweight, simplified and durable.

- With unique minimal structure design, HE body provides long life while minimizing weight for increased payload.

- HE body sized and configured to meet the specific needs of the mine, dictated by fragmentation, abrasion, cohesion and the loading tool.