336 GC

The Cat® 336 GC excavator balances productivity with easy-to-use controls, a new comfortable cab, improved fuel efficiency by up to 5 percent, and longer maintenance intervals that reduce maintenance costs up to 15 percent – all to give you a durable, low-cost per-hour excavator for your applications.

Not all features available in all regions. Consult your Cat dealer for specific configurations available in your region.

Not all features available in all regions. Consult your Cat dealer for specific configurations available in your region.

Net Power - ISO 9249

259 HP

Engine Power - ISO 14396

261 HP

Engine Model

Cat C7.1

Specification

Value

Net Power - ISO 9249

259 HP

Engine Power - ISO 14396

261 HP

Engine Model

Cat C7.1

Bore

4 in

Stroke

5 in

Displacement

433 in³

Specification

Value

Main System - Maximum Flow

559 l/min (148 gal/min)

Maximum Pressure - Equipment

5076 psi

Maximum Pressure - Travel

5076 psi

Maximum Pressure - Swing

4061 psi

Specification

Value

Swing Speed

8.74 r/min

Maximum Swing Torque

101168 ft·lbf

Specification

Value

Operating Weight

74800 lb

Specification

Value

Fuel Tank Capacity

158.5 gal (US)

Cooling System

4.9 gal (US)

Engine Oil

5.3 gal (US)

Swing Drive - Each

4.8 gal (US)

Final Drive - Each

2.1 gal (US)

Hydraulic System - Including Tank

98.5 gal (US)

Hydraulic Tank

42.5 gal (US)

Specification

Value

Boom

Reach 6.5 m (21'4")

Stick

Reach 3.2 m (10'6")

Bucket

HD 1.88 m³ (2.46 yd³)

Shipping Height - Top of Cab

10.4 ft

Handrail Height

10.4 ft

Shipping Length

36.6 ft

Tail Swing Radius

11.6 ft

Counterweight Clearance

4.1 ft

Ground Clearance

1.7 ft

Track Length

15.1 ft

Track Length to Center of Rollers

11.8 ft

Track Gauge

8.5 ft

Transport Width

10.5 ft

Specification

Value

Maximum Digging Depth

24.7 ft

Boom

Reach 6.5 m (21'4")

Stick

Reach 3.2 m (10'6")

Bucket

HD 1.88 m³ (2.46 yd³)

Maximum Reach at Ground Level

36.3 ft

Maximum Cutting Height

33.8 ft

Maximum Loading Height

23.2 ft

Minimum Loading Height

8.5 ft

Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

24.1 ft

Maximum Vertical Wall Digging Depth

18.6 ft

Bucket Digging Force - ISO

44350 lbf

Stick Digging Force - ISO

33160 lbf

- The excavator is 5 percent more fuel efficient than the 336D2 in similar applications.

- The C7.1 engine meets China Nonroad Stage III emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- Match the excavator to the job with two power modes. Smart mode automatically matches engine and hydraulic power to digging conditions, providing max power when needed and reducing power when it isn’t to help save fuel.

- The advanced hydraulic system provides the optimum balance of power and efficiency while giving you the control you need for precise digging requirements.

- Valve priority puts hydraulic pressure and flow where you command it to go for fast light- to medium-load cycle times.

- Advansys™ bucket tips increase penetration and improve cycle times.Tip changes can be done quickly with a simple lug wrench instead of a hammer or special tool, improving safety and uptime.

- Add auxiliary hydraulics to do more work with various Cat attachments.

- Product Link™ comes standard so you can remotely monitor machine health, location, hours, and fuel consumption on demand through the VisionLink® online interface.

- Work up to 3300 m (10,830 ft) above sea level.

- Standard high-ambient temperature capability is 52° C (125° F) with cold start capability at –18° C (0° F).

- Automatic hydraulic oil warm up gets you to work faster in cold temperatures and helps prolong the life of components.

- Two levels of filtration protect the engine from dirty diesel fuel.

- Grease sealed between track pins and bushings reduces travel noise and prevents debris from entering to increase undercarriage life.

- The center track guiding guard helps keep the excavator track aligned when traveling and working on slopes.

- The sloped track frame prevents mud and debris accumulation, helping reduce risk of track damage.

- The Comfort cab has a wide seat that adjusts for operators of all sizes.

- Control the excavator comfortably with easy-to-reach controls all located in front of you.

- Standard automatic climate control keeps you at the right temperature all shift long.

- Advanced viscous mounts reduce cab vibration by up to 50 percent over previous excavator models.

- Stow your gear with plenty of in-cab storage beneath and behind the seat, overhead, and in the consoles.

- Use the standard radio’s USB ports and Bluetooth® technology to connect to personal devices.

- Start the engine with a push button; use a Bluetooth key fob, smartphone app, or Operator ID passcode.

- Program each joystick button, including power mode, response, and pattern, using Operator ID; the machine will remember what you set each time you go to work.

- Navigate quickly on the standard high-resolution 203 mm (8 inch) touchscreen monitor or with the aid of the jog dial control.

- Protect your hammer from overworking. Auto hammer stop warns you after 15 seconds of continuous firing and then automatically shuts it off after 30 seconds — all to prevent wear and tear on the attachment and excavator.

- Not sure how a function works or how to maintain the excavator? Always have the operator's manual at your fingertips in the touchscreen monitor.

- The Cat Locator is a Bluetooth device that makes finding your attachments and other gear quick and easy. The excavator's onboard Bluetooth reader or Cat App on your phone will locate the device automatically.

- Expect up to 20 percent less maintenance cost than the 336F due to extended service intervals (savings calculated over 12,000 machine hours).

- Check hydraulic system oil and easily drain fuel system water and fuel tank water from ground level.

- Track your excavator’s filter life and maintenance intervals via the in-cab monitor.

- Using Cat genuine oil and filters and doing your typical S∙O∙S monitoring will double the current service interval to 1,000 hours, giving you greater uptime to do more work.

- Oil and fuel filters are grouped and located on right-hand side of machine for easy maintenance.

- The new air intake filter with pre-cleaner has double the dust holding capacity of the previous air intake filter.

- The new hydraulic oil filter provides improved filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and longer life with a 3,000 hour replacement interval – 50 percent longer than previous filter designs.

- S·O·S ports are on ground level, simplifying maintenance and allowing for quick, easy extraction of fluid samples for analysis.

- Keep your excavator secure with Operator ID. Use your PIN code on the monitor to enable the push button starting feature.

- The standard ROPS cab meets ISO 12117-2:2008 requirements.

- A travel direction indicator helps operators know which way to activate the travel levers.

- A ground-level shutoff switch stops all fuel to the engine when activated and shuts down the machine.

- Enjoy great visibility into the trench, in each swing direction, and behind you with the help of smaller cab posts and larger windows.

- Serrated steps and anti-skid punch plate on the service platform help prevent slipping.

- A rearview camera is standard.

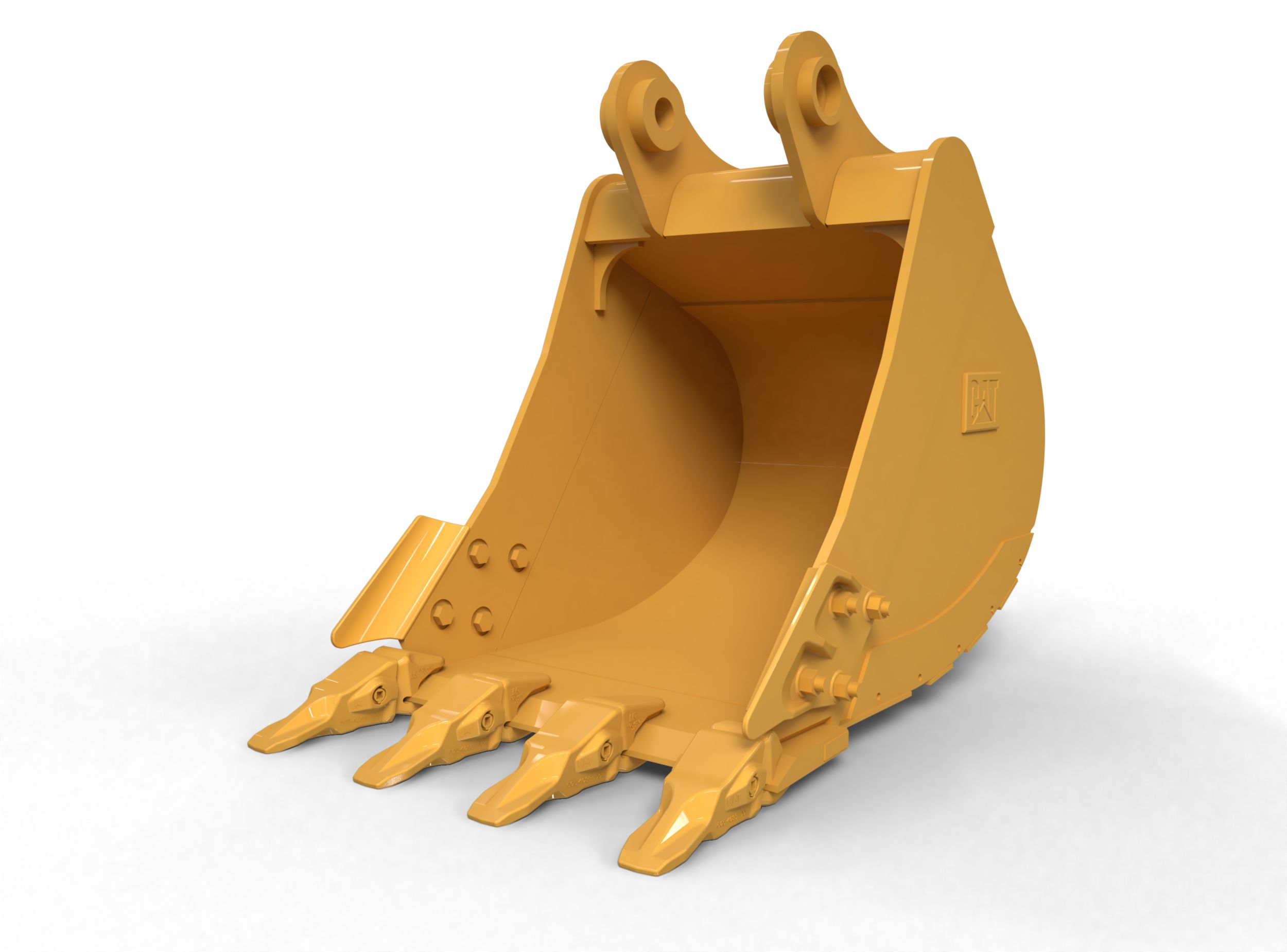

General Duty Bucket 1650 mm (65 in): 540-4108

General Duty Bucket 1500 mm (59 in): 561-0625

General Duty Bucket 1650 mm (65 in): 541-1739

General Duty Bucket 1650 mm (65 in): 540-4111

General Duty Bucket 1000 mm (39 in): 550-9470

General Duty Bucket 1500 mm (59 in): 541-1738

General Duty Bucket 1800 mm (71 in): 540-4110

General Duty Bucket 1650 mm (65 in): 541-1741

General Duty Bucket 1650 mm (65 in): 540-4076

General Duty Bucket 1650 mm (65 in): 540-4077

General Duty Bucket 1800 mm (71 in): 541-1742

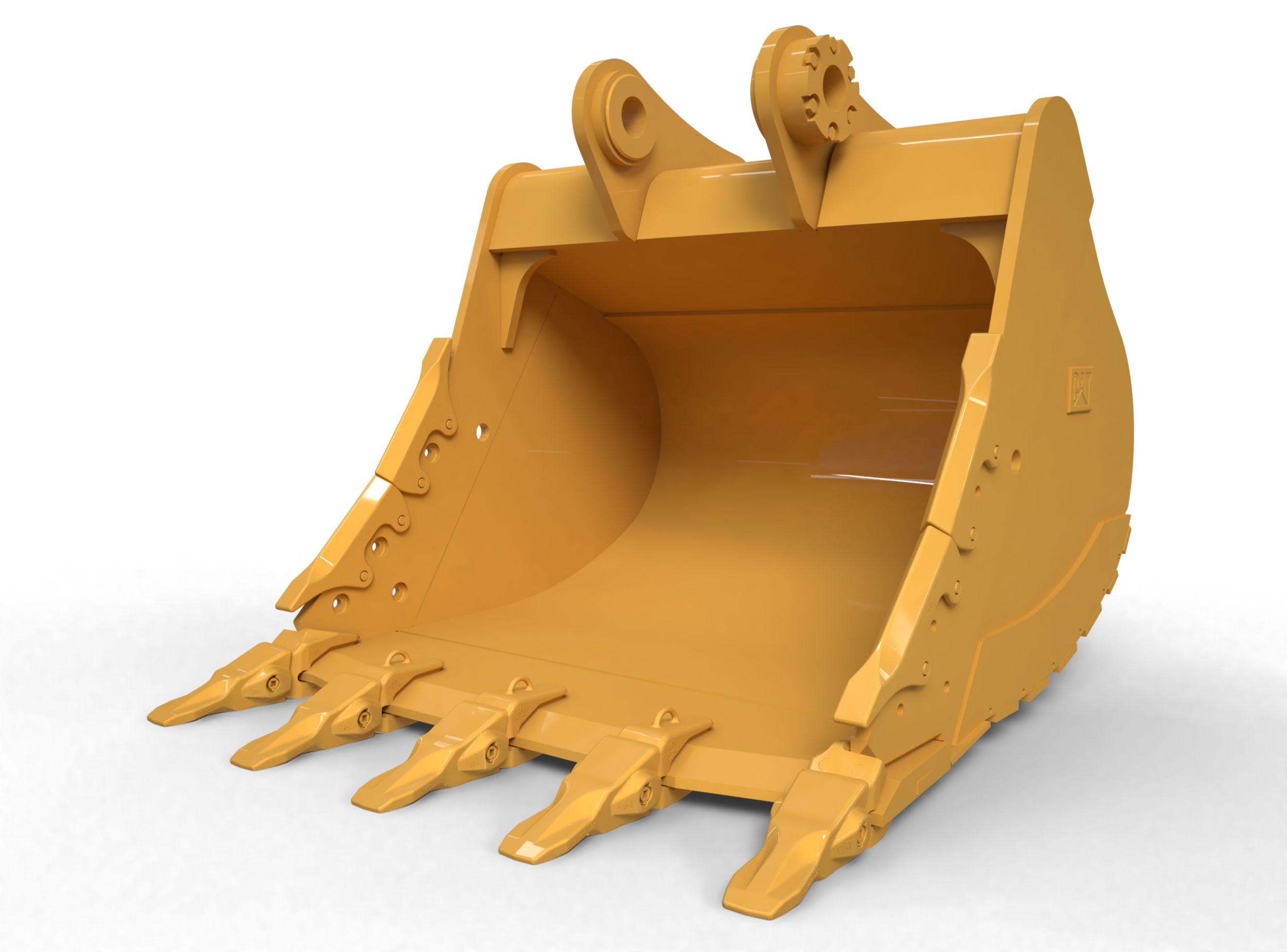

Extreme Duty Bucket 1700 mm (67 in): 518-9331

Extreme Duty Bucket 1950 mm (77 in): 528-8154

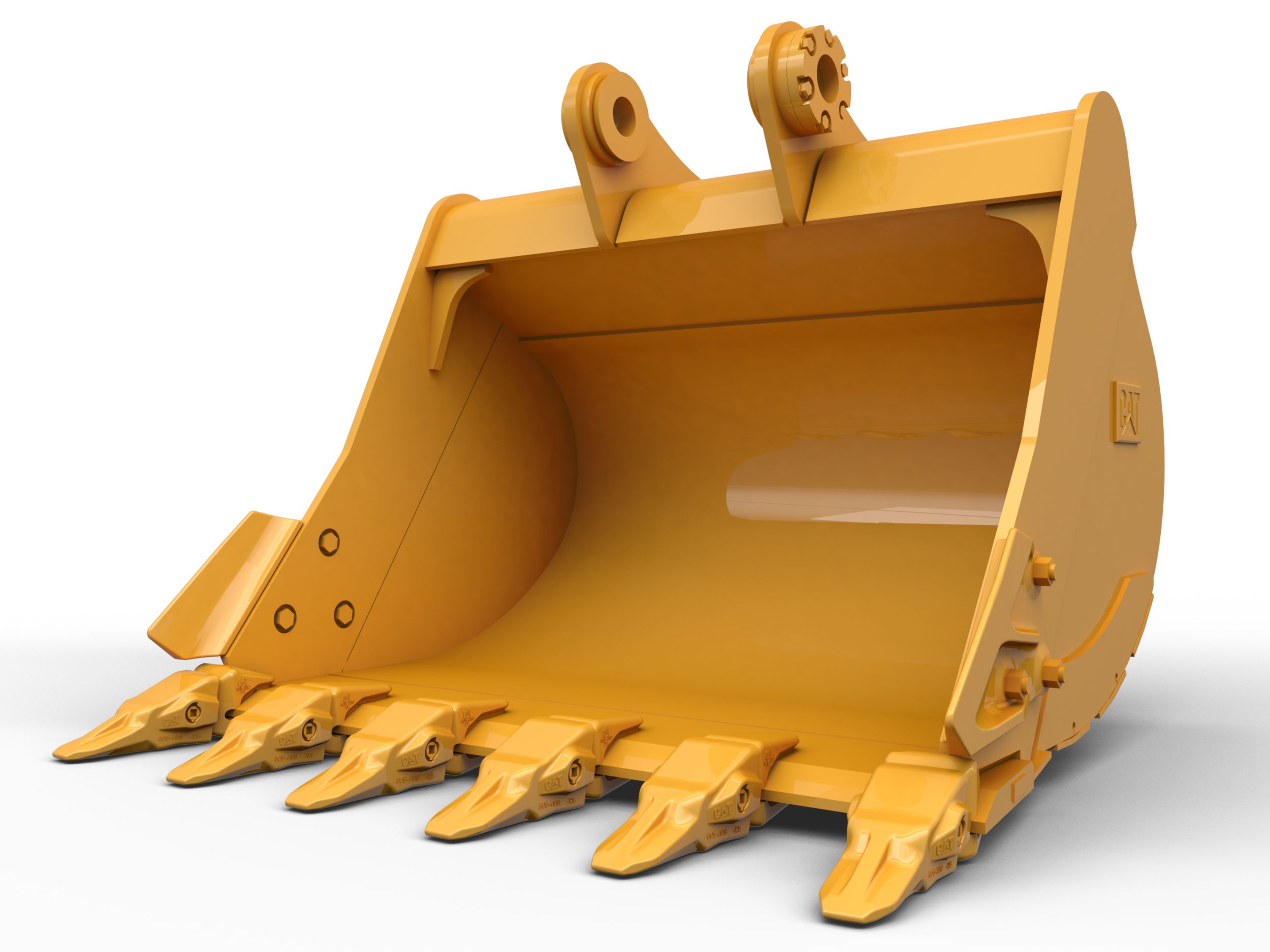

Heavy Duty Bucket 1350 mm (54 in): 528-4603

Heavy Duty Bucket 1050 mm (42 in): 558-7939

Heavy Duty Bucket 1500 mm (60 in): 528-4669

Heavy Duty Bucket 1850 mm (72 in): 528-4610

Heavy Duty Bucket 1650 mm (66 in): 528-4662

Heavy Duty Bucket 1650 mm (66 in): 528-4664

Heavy Duty Bucket 1750 mm (69 in): 577-0344

Heavy Duty Bucket 1500 mm (60 in): 528-4590

Heavy Duty Bucket 1500 mm (60 in): 528-4561

Heavy Duty Bucket 1650 mm (65 in): 528-4591

Heavy Duty Bucket 1650 mm (66 in): 528-4594

Heavy Duty Bucket 1650 mm (66 in): 528-4564

Heavy Duty Bucket 1650 mm (66 in): 528-2204

Heavy Duty Bucket 1850 mm (72 in): 566-6632

Heavy Duty Bucket 1900 mm (74 in): 528-4548

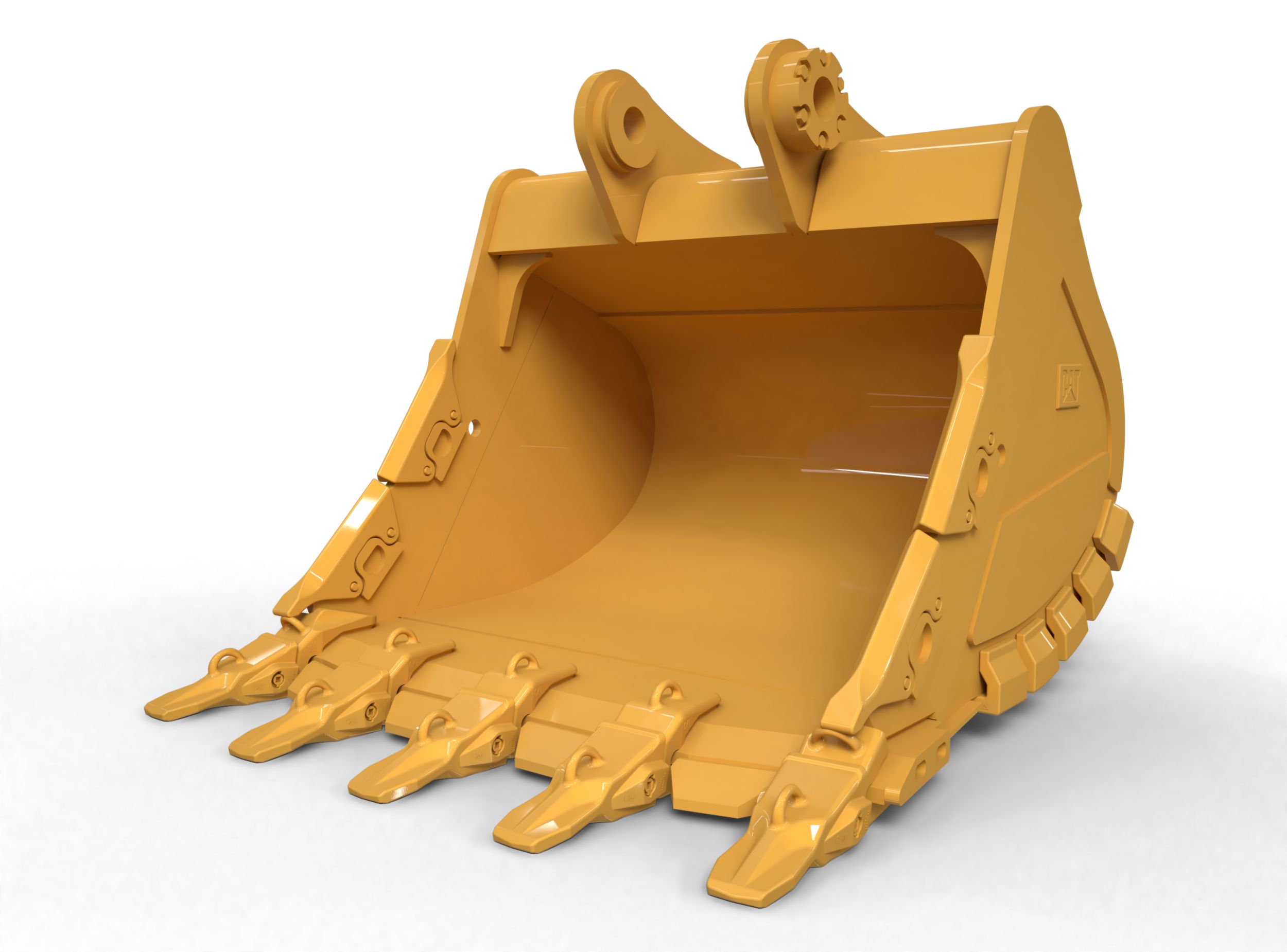

Severe Duty Bucket 1500 mm (59 in): 528-4668

Severe Duty Bucket 1500 mm (59 in): 528-4645

Severe Duty Bucket 1350 mm (54 in): 528-4665

Severe Duty Bucket 1350 mm (54 in): 554-3128

Severe Duty Bucket 1650 mm (66 in): 528-4667

Severe Duty Bucket 1550 mm (61 in): 518-9327

Severe Duty Bucket 1700 mm (67 in): 518-9328

Severe Duty Bucket 1650 mm (66 in): 551-2213

Severe Duty Bucket 1650 mm (66 in): 528-4592

Severe Duty Bucket 1650 mm (66 in): 528-4585

Severe Duty Bucket 1650 mm (66 in): 558-6618

Severe Duty Bucket 1650 mm (66 in): 528-4593

Severe Duty Bucket 1900 mm (75 in): 528-8155

Severe Duty Bucket 1900 mm (75 in): 518-9330

Ditch Cleaning Bucket 1800 mm (72 in): 462-8433

Ditch Cleaning Bucket 2000 mm (79 in): 462-8434

Ditch Cleaning Bucket 2400 mm (94 in): 462-8438

Ditch Cleaning Bucket 2200 mm (87 in): 462-8441

Ditch Cleaning Bucket 2200 mm (87 in): 462-8440

Ditch Cleaning Bucket 2400 mm (94 in): 456-2378

Ditch Cleaning Bucket 2400 mm (94 in): 462-8431

Utility Duty Bucket 1600 mm (64 in): 357-9453

Utility Duty Bucket 1700 mm (67 in): 186-6744

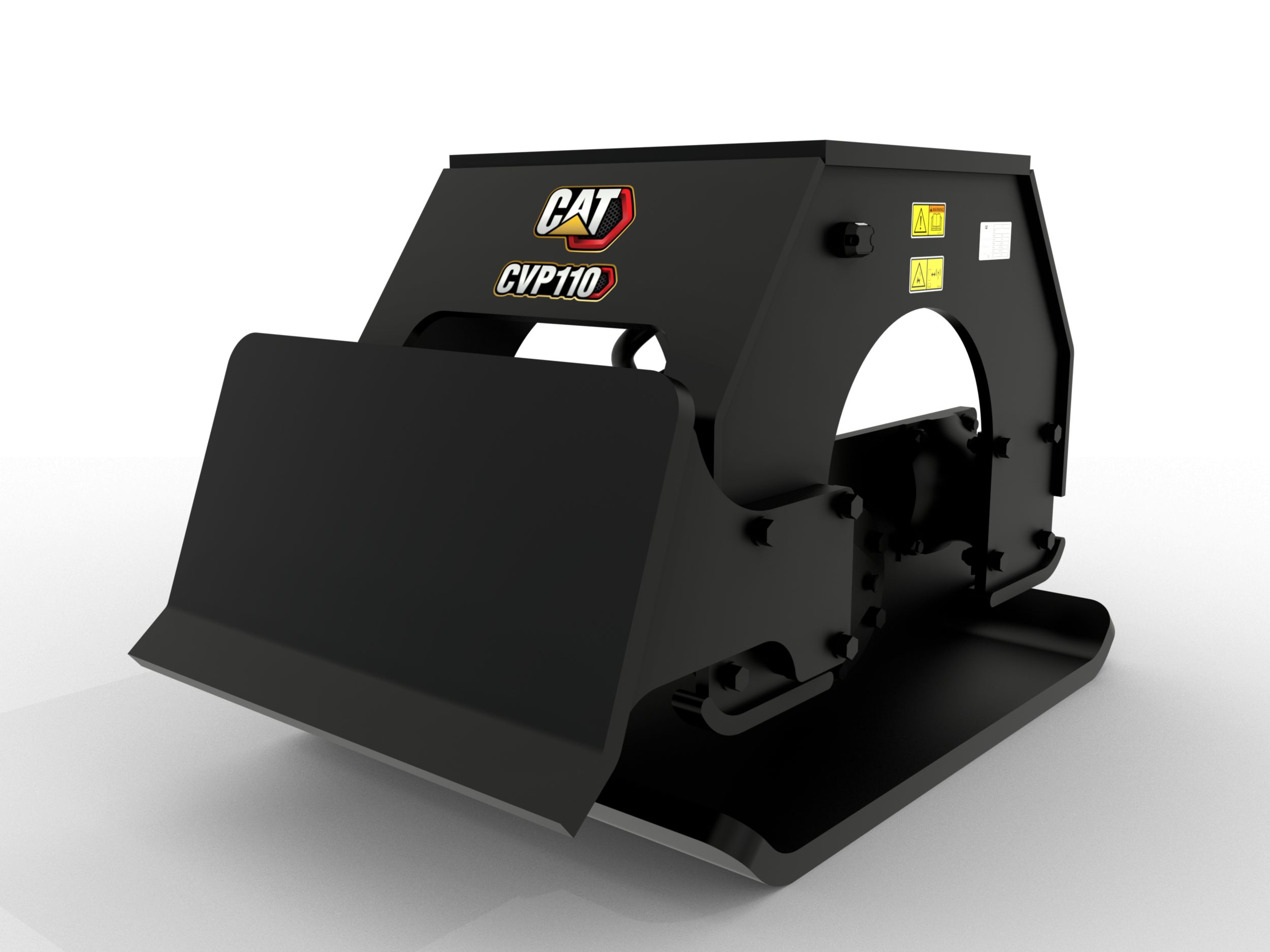

CVP110

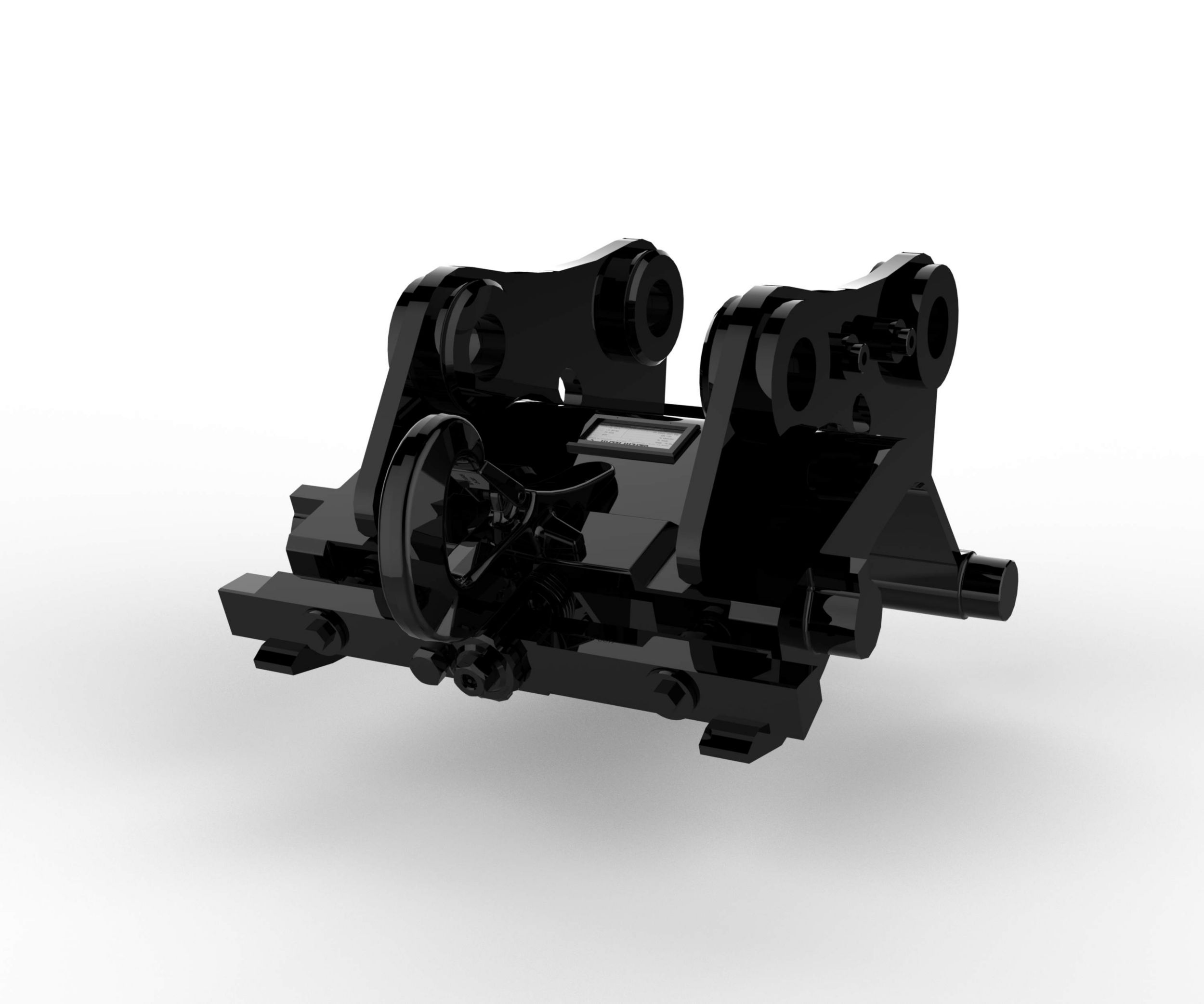

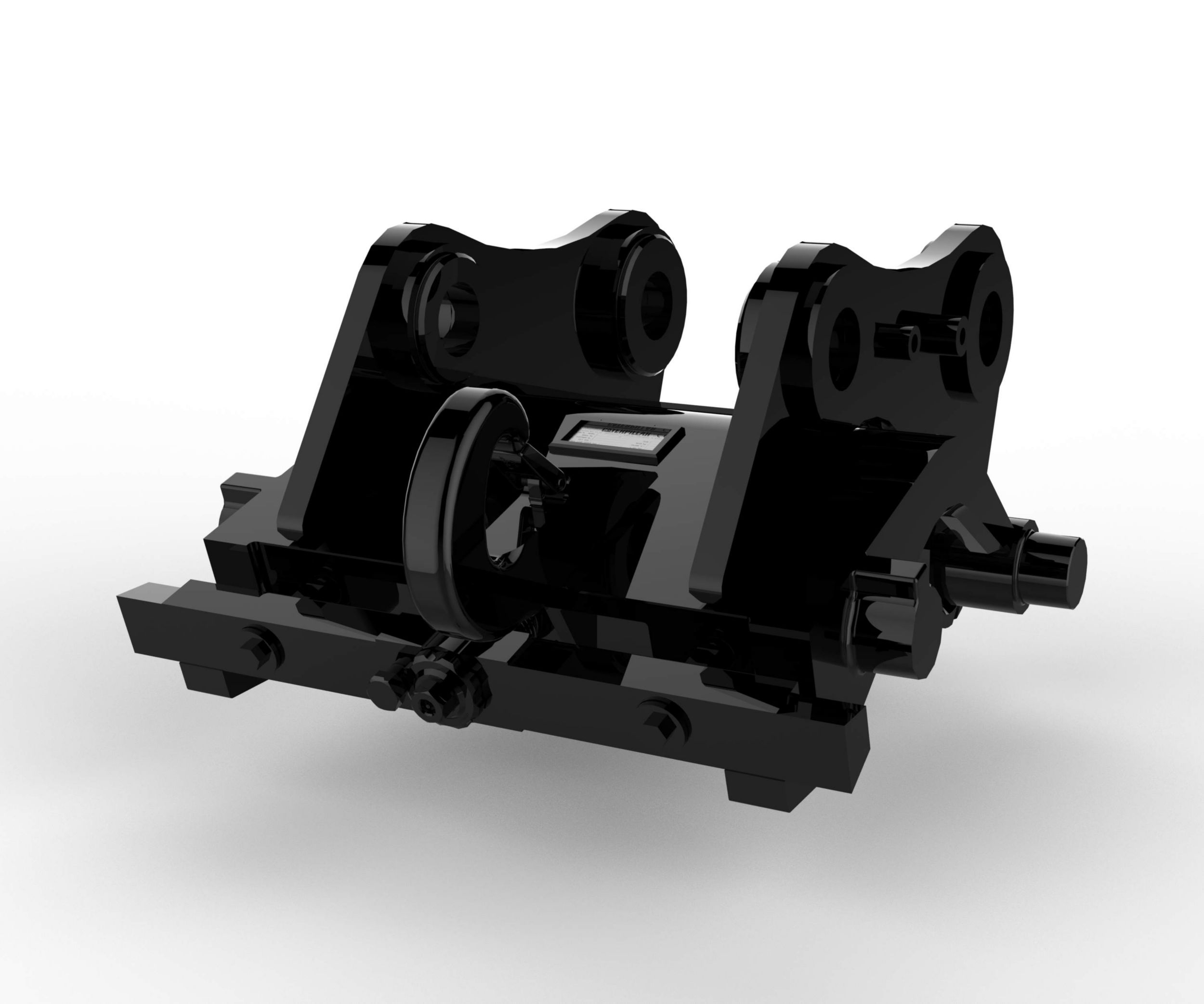

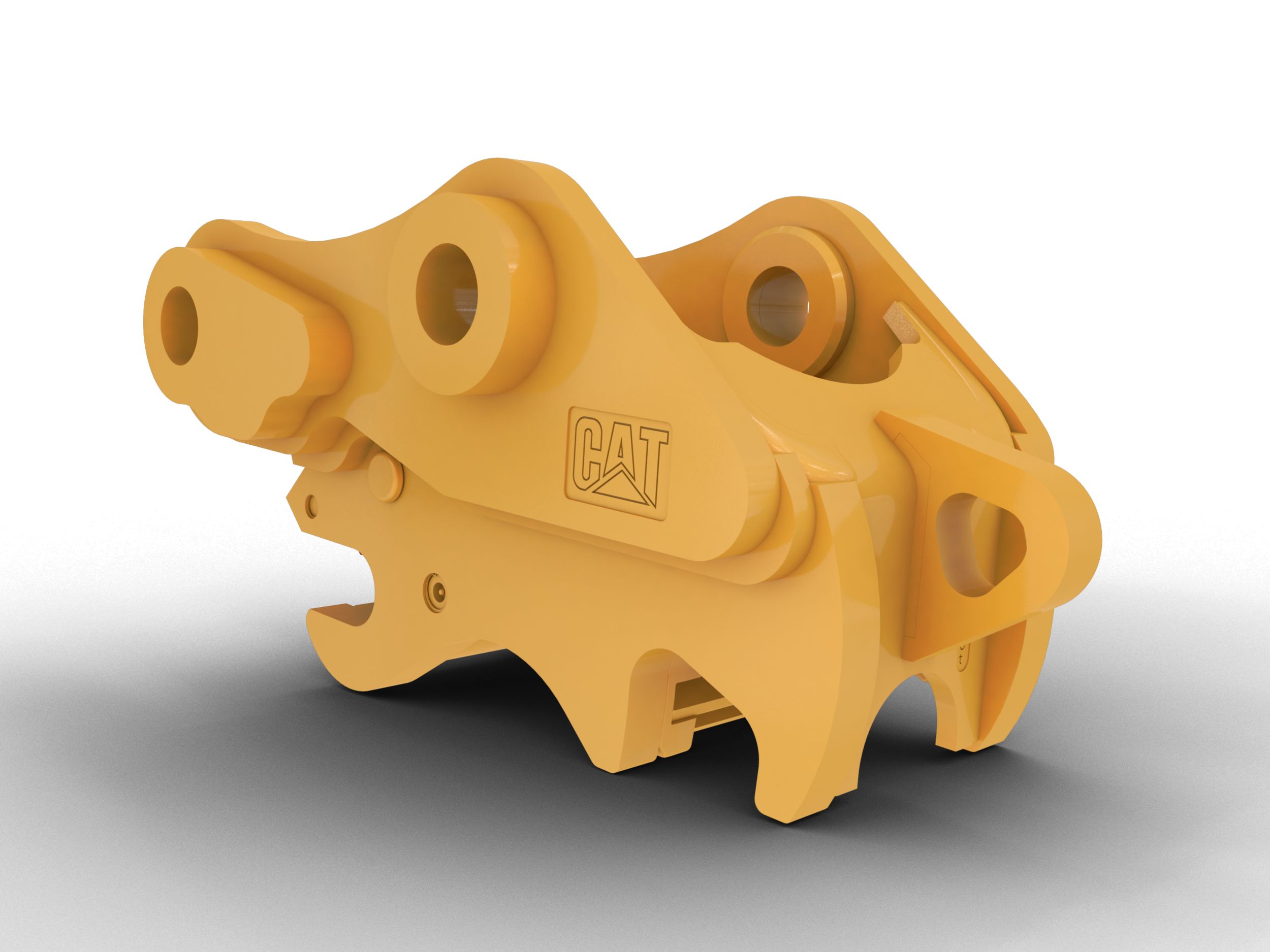

CW-45S

CW-40S

CW-40S

CW-45S

CW-55S

CW-55S

CW-45

CW-40

CW-55

CW-45

CW-40

CW-55

Pin Grabber Coupler (B-Linkage): 455-3909

G332 Demolition & Sorting Grapple: 587-8991

G345 Demolition & Sorting Grapple: 608-0756

G318 Demolition & Sorting Grapple: 587-8965

G317 GC Demolition & Sorting Grapple: 587-8721

G318 WH Demolition & Sorting Grapple: 587-8970

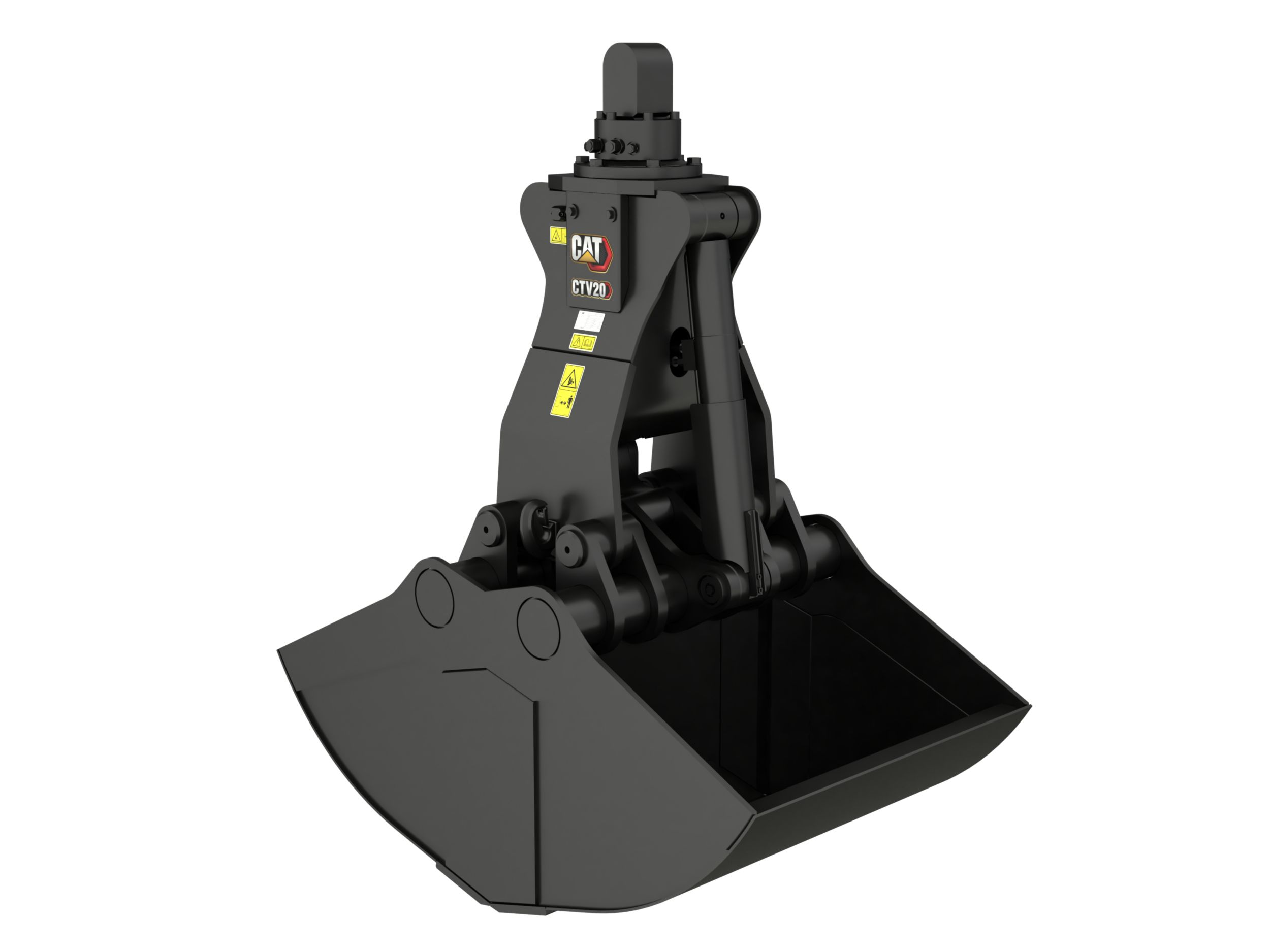

CTV20-1300 Clamshell Grapple

CTV20-1500 Clamshell Grapple

CTV20-1700 Clamshell Grapple

CTV20-1900 Clamshell Grapple

CTV20-2300 Clamshell Grapple

CTV20-1500-BOCE Clamshell Grapple

CTV20-2300-BOCE Clamshell Grapple

CTV30-1700 Clamshell Grapple

CTV30-1900 Clamshell Grapple

CTV30-1900-BOCE Clamshell Grapple

GSH420 4-Tine, 500-Liter Orange Peel Grapple

GSH420 4-Tine, 600-Liter Orange Peel Grapple

GSH420 4-Tine, 750-Liter Orange Peel Grapple

GSH520 5-Tine, 500-Liter Orange Peel Grapple

GSH520 5-Tine, 600-Liter Orange Peel Grapple

GSH520 5-Tine, 750-Liter Orange Peel Grapple

GSH525 5-Tine, 750-Liter Orange Peel Grapple

GSH555 5-Tine, 1000-Liter Orange Peel Grapple

GSH455 4-Tine, 1000-Liter Orange Peel Grapple

GSH455 4-Tine, 1500-Liter Orange Peel Grapple

H140 GC

H120 GC

H120 GC S

H160 GC

H180 GC

H180 GC S

H160 GC S

H115 S

H140 S

H160 S

MP324 Demolition Jaw

MP318 Demolition Jaw

MP324 Universal Jaw

MP318 Universal Jaw

MP324 Pulverizer Jaw

MP318 Pulverizer Jaw

MP324 Concrete Cutter Jaw

MP324 Shear Jaw

MP318 Shear Jaw

MP324 Tank Shear

1290mm (51in) Ripper

S2050 Straight Scrap & Demolition Shear

S3035 Rotating Scrap & Demolition Shear

Cat® Detect with Smart Camera

G318 Demolition & Sorting Grapple: 587-8966

GSH425 4-Tine, 1150-Liter Orange Peel Grapple

GSH425 4-Tine, 750-Liter Orange Peel Grapple

GSH425 4-Tine, 950-Liter Orange Peel Grapple

GSH525 5-Tine, 1150-Liter Orange Peel Grapple

GSH525 5-Tine, 950-Liter Orange Peel Grapple

MP318 Concrete Cutter Jaw

RC20